In my last post, I confirmed the notion that fluids under pressure always obey the laws of physics. Fluids will flow towards the low pressure outlet every time – the path of least resistance, as it were. With this in mind and my back on the mend, I carefully boarded Cay of Sea today and set about to understand how I could have plumbed the overboard holding tank circuit in the wrong direction. Regardless of what I intended the plumbing design to do, it nevertheless obeyed the laws of physics perfectly and moved seawater into the holding tank, not out.

There were several possibilities as to why: 1) I had the Y-valve hooked up wrong; 2) I had the inlet and outlet hoses reversed; or 3) the opposite/but same effect – I had assembled the pump with the valves reversed.

It was number 3, actually. I dimly remembered from two years ago (as I was tracking down hoses and confirming their connections) telling myself that I had to reverse the assembly of the pump so it would pump 180 degrees from its current configuration. I didn’t do that when I reassembled it last week, so it very naturally drew water from the seacock which is intended to be the exhaust. I had the hoses off and the pump disassembled/reassembled in about 45 minutes.

By the way, a heat gun is the required tool for managing white sanitation hose. It simply is not possible to work with it any other way. When warmed up, it’s nice and pliable.

I also removed the vented loop from the holding tank exhaust. Yeah, that was an important move, seeing that its not possible to inject air at the top of the loop without creating a corresponding leak. However, not many people I know want this sort of leak in their boat. No, not at all. These loops, of course, are “necessary” for breaking any syphon that can flood the boat. I had suspected, but wasn’t sure, that this would allow “material” to leak out of the pathway to overboard. I was right, of course, because that’s the way they are supposed to work. However, it’s one of those details that “experts” fail to tell you as you read up on the subject. The “experts” emphasize the importance of having a vented loop in any line that is connected to an overboard fitting. I know, I know – you would think I could have worked that out for myself without being told. Well, I did eventually – and I learned this fact while pulling in seawater, not pumping out waste, so I feel thankful that I was spared that misery. Also, there is no risk of a syphon my case, because I close the overboard valves when the operation is complete. I will never leave that seacock in the open position.

You may also remember that I used flexible bilge pump hose for one of the tight bends in the circuit. I think that is going to work fine for two reasons: 1) I got the hose to seal on to the fittings with no problems, and 2) there will be no waste standing in this hose, as the pump has enough power to push all the fluid out of the hose. Besides, anytime I will use this pump-out option, it will include a clean seawater rinse of the system. Nothing objectionable will be left in the hose.

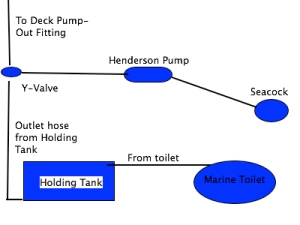

I reconnected the hoses with the pump reconfigured, and successfully evacuated the holding tank in about 3 minutes. Pumped in a little more seawater from the toilet, evacuated the tank again. All’s well. No leaks, no problems. Here’s a rough diagram detailing the overboard circuit:

Tuesday, September 2, 2014

Plumbing in the Right Direction

Over on s/v Cay of Sea, Rick tackles his head plumbing. He faces a problem that I completely understand - when Eolian's holding tank was plumbed at the factory, the connections to the inlet and the outlet were reversed, making the deck pump-out fitting completely useless...

Labels:

head,

plumbing,

s/v Cay of Sea

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment