Please welcome new contributor Marc of

s/v Alchemy (and s/v

Valiente)! Marc 's two boats, one steel and one fiberglass, give him a unique perspective. For his first contribution to Small Boat Projects, Marc faces the reboarding problem: How to board the boat from the water...

|

| Drastic steps were required. |

Apparently, I have readers who worry when the pace of my blog posting slackens somewhat. Often, that's either because I have little to say, or it isn't particularly interesting (or is even less interesting than the usual not-very-interesting boat blagging), or I have to down boat tools and apply myself to money-making for the boat habit. Such has been the case recently.

It's also been the hottest part of the summer, making the interior of the steel beast intolerable even for those, like me, used to panting in its torrid, insufficiently ventilated bowels. Now, if that description hasn't been off-putting enough, I'll recount a recent repair gig on the old plastic fantastic, Valiente.

A boarding ladder bought last year to replace a previously busted ladder itself improvidentally folded the wrong way while I was descending for a swim. I'm considerably lighter than I was this time last year, so I blame shoddy construction. Irrespective of that, getting back aboard was a trial and I bear the bruises and cuts to prove it. So I determined to do better, meaning sturdier and stronger.

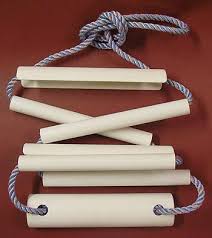

In our part of the world, ladders are required for the purposes of rescues, for which having at least one aboard is a mandatory safety equipment item, like flares, and of course for swimming and reboarding a boat at anchor. There are many ways to mount and deploy the many types of boarding ladder, which range from simple rope ladders...

|

| Uh, no. |

...to heavy duty welded jobs that would suit the stern of Alchemy...

|

| Note: Not the stern of Alchemy. |

There are plenty of boarding ladder options, most of which are spendy. There are folding, telescoping, single leg and even fairly novel ideas:

|

| Novel is also expensive, although I think firemen use something like this. |

All of which got filed for when the time comes to address this on Alchemy, probably at the same time I address the conceptually linked issue of "what mast step can possibly fit my giant feet". In the meantime, Valiente needed a new, unbusted and stronger ladder for the preferred amidships location (the stern is too narrow in my view and too hard to access for backing plates to bolt a ladder there).

Due to a chance perusal at the chandlery where my wife works, I picked up a ladder not only of a type I had yet to see: a gunwale-mounted aluminum ladder that was light, of a good width and which folded vertically.

|

| Nice and long, too, meaning a couple of steps are below WL |

|

|

This ladder, the maker of which is not on the label, was the right price by virtue of looking pretty industrial and having hung, neglected, on the wall of more stainless, hot 'n' happening models. Maybe it's for a dock. I am indifferent. I want its functional length and its stowage compactness.

|

| Ignore the general grubbiness. This was prior to a Big Summer Scrub/Debirding |

Looks like a real house ladder, doesn't it? For me, this is a Good Thing, given how lame and plasticky swim/boarding ladders have seemed to me.

|

| See previous repairs and former mount points. Also 40-year-old chrome on bronze. Sigh. |

Installation was straightforward, if longish, as I decided on a proper "drill 'n' fill" process of oversizing the mounting holes, isolating the balsa core with thickened epoxy (West System) and then drilling the proper-sized bolt holes (3/8") through the resultant "hard core".

|

| Slightly blurry...or was that the epoxy kicking? |

The mounting plates were sealed around their edges with 4200, as were the bolts themselves. As the bolts are snugged down, the "bead" of sealant climbs up the threads, making a further gasket of sorts under the bolt head and in the drilled hole itself, without mucking up the part the nuts and washers go on. This greatly lessens, for the years I've been doing it, the chances of rain or seawater migrating below, which can really ruin your Little Library of Boat Repair, in my unfortunate and pre-smartening-up experience.

|

| Evidence of my previous labours |

After letting the epoxy fill cure, the holes were drilled and "backing plates" in the form of largish fender washers were installed; my son held the bolts still while I used a 1/4" ratchet driver to dog down the nuts to an acceptable degree (Note to self: must get a "clicky torque wrench" in order to quantify "acceptable degrees"). The line of larger bolts running aft is the port genoa track, fixed after it tore straight out of the deck at 28 knots. Has not budged since the recore and remounting!

|

| Might have to consider repainting the interior at some point as this is getting old. |

A closer look: The tape was there to keep the epoxy from dripping, but leaving this piece in place is a tell-tale. As it is paper painters' tape, if it feels damp, you've got a leak and a sealing job ahead. Not damp so far after several drenchings of mid-summer intensity.

|

| Will swim shortly, applying the ultimate field (stream?) test |

The finished project looks good to me and packs down even better into the starboard cockpit locker than did its crappy forebear. I saw on a sailing forum an idea to get the ladder more vertical vis-a-vis the turn (in) of the hull by lashing crosswise a foam pad or a small fender under the ladder. This sounds like a smart (and cheap!) idea I will employ.

|

| Cleverness courtesy of Cruisers' Forum's "David Old Jersey" |

Once again, needful work on Valiente leads to applicable solutions (or at least, bad ideas probably avoided) on Alchemy.

No comments:

Post a Comment