When we moved the boat to Fiddlers Cove Marina we had an instant fly problem. They came from nowhere. We’d been talking about gettting or making hatch covers before we moved and found them to be very expensive from West Marine so Natalie decided to make them herself.

We bought fiberglass screen material from Home Depot and had some leftover Sunbrella from when the sail covers were made. The pattern was pretty basic, just two triangles for the sides of the hatches and then a rectangle to cover the front and back. The bottom was made from Sunbrella and filled with rocks. We could have used lead shot, but decided against that because of toxicity.

After Natalie made 3 hatch cover screens a friend asked for a price for Natalie to make some for him so we searched online and found the old WestMarine hatch covers still cost almost $90, and that there’s a new competitor that only costs only $30-$40 for their largest size. Had we known that there was a lower priced offering we’d have just bought the $30 hatch covers.

Life aboard is living large, in a small space. Every boat owner has found ways to make life in that small space easier, more comfortable, more convenient. The idea behind this site is to provide a place where these ideas can be shared amongst the boating community. To participate, send your contribution to SmallBoatProjects at gmail dot com.

Pages

▼

Thursday, July 31, 2014

Homemade Hatch Cover Screens

Facing a fly problem, Nate and Natalie aboard s/v Astrea sewed up their own custom-fitted hatch screens:

Thursday, July 24, 2014

Another Pump Rebuild – Henderson Mk V Bilge/Diaphragm Pump

Rick on s/v Cay of Sea is on a pump rebuilding tear...

My service kit arrived today for this Henderson Mk V manual bilge pump, so I took some time this afternoon to rebuild it. This was the easiest rebuild of the four different type pumps that are on Cay of Sea.

The Henderson pump is actually destined for use as a holding tank evacuation pump. When we go off shore (eventually), I want to be able to empty the holding tank overboard. I discuss my refit of the sanitation system on board Cay of Sea here.

Above are images of the very large and bulky pump body. The bottom and top halves are fastened with 8 self-tapping screws, and the diaphragm also serves as a gasket between the halves. The casting and labeling seen above actually identify this pump as a “Blakes Lavac” pump, but it is a Henderson Mk V. It is supplied by Lavac (and labeled as made by them!) as their preferred pump for their vacuum-operated marine toilets.

There are only a few parts in the service kit: Two valves, an O-ring gasket, and the big rubber diaphragm are the heart of the kit. It also comes with new stainless fasteners and snap retainers for pivot shafts.

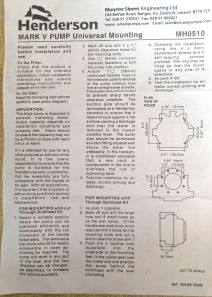

The instructions are useful, including a complete parts inventory reference, plus the various options and requirements for installation. I was a bit dismayed by one of the parts supplied: the “joker” valve, or back flow preventer, was distorted and looked to be in worse shape than the joker valve I was replacing. While the rubber of the new one was slightly more supple, the distortions in shape made me doubt that it would close properly when pulling a vacuum. I cleaned the old one, lubricated it with dish soap, and reinstalled it. The joker valve is held in place with four stainless screws. It’s easy to remove and replace.

Here are a couple of photos of the pump halves separated. You can see the orientation of the valves and diaphragm.

The diaphragm is moved by a lever which is attached to an actuator arm. The end of the arm is threaded to received a large diameter nylon nut. Two large plastic plates mount onto the actuator arm and are secured in place by the nut. Photos make this easier to understand than text.

I see now that I forgot to get a photo of the actuator arm without the diaphragm in place. Sorry, guess you’ll have to refer to the illustration (above) for that. I did not remove the actuator – there was no need to.

I also replaced the old flapper valve (think of a one-way door) with the new one from the kit.

I installed the new diaphragm, reassembled the pump halves, carefully tightened the screws all around as evenly as possible, and continuously checked the gasket contact area for fit and seal. After it was put back together, I checked the pump by inserting the handle into the socket and pumping it while checking for suction with my hand. It pulled well – unlike before. I’m not sure which component was the culprit – perhaps an accumulation of little leaks throughout – at any rate, it works now.

I’ll review its installation in the head in another post.

Tuesday, July 22, 2014

How to bend shower track

Mike of s/v Chalice takes us thru the process. With the right tools, jigs and with the secret ingredient, it is easy!

So just how do you do it with out it collapsing?

First I borrowed a Harbor Freight bender from a friend of mine to see if I could do it. Then I had to make a jig to work with the bender. Lastly, test on some scrap ( old piece).

The Jig build.

From update _10_1_2012

From update _10_1_2012

From update _10_1_2012

With me so far? The half inch ply was a perfect fit. But if not I would have glued spacers in if needed.

From update _10_1_2012

On the bender.

From update _10_1_2012

Ok, so what is the secret ingredient? I actually found it on an Chinese industrial website for industrial benders. Dead simple when you know. It is a spacer/filler. Made from a piece of scrap plastic/Delrin.

Insert it in the track. It MUST be a tight fit.

Add captionFrom update _10_1_2012

From update _10_1_2012

Now bend it.

From update _10_1_2012

First test on scrap. Then buy some track. I got mine here: http://www.curtain-tracks.com/ My problem was I had to match my current track. If you don't have to do this, then you may want to go a different route.

From update _10_1_2012

More bending.

From update _10_1_2012

Finished piece.

From update _10_1_2012

I hope this helps anyone who needs to bend some track. It's not hard and can be done fairly inexpensively. If you have friend with a bender. I should say that of course this is not the only way to do it. It's just the way I did it.

Tuesday, July 15, 2014

Tilley hats

Real customer service seems to be a rarity these days. When it is found, I like to highlight it.

Please welcome new contributor Adam, aboard nb Briar Rose!* Adam sings the praises of a company which I suspect has many customers among the readers of this blog:

Please welcome new contributor Adam, aboard nb Briar Rose!* Adam sings the praises of a company which I suspect has many customers among the readers of this blog:

My Tilley hat has become something of a trademark -- and I often get people saying they recognised me because of it. But lately it's been looking a bit worse for wear, and when it came out of the wash a week or so ago,the front was full of little holes. It's maybe not surprising, given how much I wear it, that it gets regularly soaked (as I like to have it on under the hood of my waterproof when it's raining), operates as a sun hat, and once had to be rescued from the canal when the wind took it (they're designed to float).* For those of you to whom it may be unfamiliar, the abbreviation "nb" stands for "narrow boat", a class of boats plying the canal network in England. The boats are constrained in size by the canals and locks they navigate, up to 70' LOA with a maximum beam of 7'.

So I emailed Tilley in Cornwall, who said the hat was covered under their lifetime guarantee never to wear out. After a few checks, they've sent a replacement. All I had to pay was a fiver for postage. It's only when you see the old and the new next to each other that you realise how battered and faded the old one is. Anyway, well done Tilley; a guarantee that really does mean something.

Thursday, July 10, 2014

Is Your Tether Quick Release Actually Quick Release?

With his typically engineering analysis, Drew over at Sail Delmarva asks some hard questions about tethers:

This tether was found by rescue workers at the Wing Nuts accident site; there were several fatalities.

This is dangerous even on deck--if the tether gets wrapped around a sheet or guy he has 2 clips to release to get free. Not good.

And this points a scary trend, where equipment companies design to standards but don't actually test the gear in the field. They give the gear to sailors to use, but that is hardly the same as structured testing where all likely use scenarios are systematically tested.

The solution? some brands are adding a ring or loop near the harness end. If you make your own, leaving the loop long enough will do. Or in my case, I simply clipped in a small biner to give myself a parking space.

The typical vendor response? You should have a knife. Please. Why not say I should fall off the boat?

(No, I don't used quick-release harness end clips. I single hand and can't imagine a senario where releasing will leave me better off. On the other hand, I can imaging the quick-release letting go or me clipping it incorrectly. My compromise. I still prefer to clip to the "parking space" and have only one clip on the harness.)

Tuesday, July 8, 2014

Rebuilding Whale V Vertical Lift Hand Pump

Aboard s/v Cay of Sea Rick continues his series detailing how to rebuild pumps; today it is a Whale hand pump:

My second pump rebuild is the Whale V. I have two of these on board – one for the drinking water system, and one for the head lavatory. They both needed rebuilding, and I completed one yesterday. Here are the photos and discussion of that process.

This rebuild was a little less straight-forward than the tiptoe pump described in the previous post. There are a few more parts, and they are very much sequentially assembled. My inevitable errors – both in disassembly and reassembly – made the process a bit more time-consuming. It is important to keep track of which parts are removed and replaced. Several of the replacement parts look very similar, so comparing the removed part with the replacement is essential. Here is a link to the exploded view and service kit. This kit costs about $15.

Unscrewing the hose fitting at the bottom of the pump provides access to the interior parts: piston, seals, o-ring gaskets, etc.

Although the instructions warn that the gasket inside the spout housing is the most difficult to replace (and recommended not doing unless absolutely necessary), I did not find that to be the case. I had to dig the old gasket out, which was slightly difficult. Then carefully compare parts to ensure I put the correct one back in place. More difficult by far was re-assembling the pump in the right order. I had to do it two or three times before I got the sequence right. It will be obvious if you get it wrong, because the piston will not go back in the cylinder if assembled out-of-order. There is a valve at the bottom of the piston that must be screwed on after the piston is back in the cylinder. It’s not complicated, really. Just takes a bit of trial-and-error.

The little gutter washers are the most problematic – these are circular rubber cups with channels in them, and there are several of them – slightly differently sized. They are easily unseated as the pump is reassembled, so you might feel like you need three hands at some point during the process. The whole process took about 30 minutes. I loosely seated the pump in its mounting location (see top photo), waiting to fasten it in place until I have re-plumbed the drinking water lines with new tubing. The hard water in our water source leaves deposits inside the lines after several years of use, then begins to flake off into the water. We filter all the water with a Brita pitcher, but the water doesn’t look very appetizing with little white floaty things drifting around in the top reservoir of the pitcher. Time to change out the lines. . .

Thursday, July 3, 2014

Invisibility, covered

This post originally appeared on Windborne in Puget Sound

It's funny, isn't it? How if you look at something long enough, it becomes invisible. Even if it is surpassingly ugly, you eventually cease to see it.

Eolian's blinds are a case in point. Having blinds is a neat idea - even neater, these were custom made for the windows. And the installer made a good materials choice, with plastic louvers instead of metal ones. But unfortunately he did a pretty poor job aesthetically. Covering the blinds with valances has been on the list since, well since we got Eolian.

First, it was necessary to procure the materials for the valances: six pieces of teak, 4' x 4" x 1/2". Then there was a lot of thinking. I had two conflicting design criteria:

Next, I epoxied blocks to the backs of the valances. Then I drilled pilot holes up thru the blocks and into the mount points. Screws hold the valances in place - accessible but not visible. (Note: when gluing teak, always wipe it down carefully ahead of time with acetone to remove the waxy teak oils from the surface.)

Next, at the nav station wire chase. The wire chase was (amazingly) exactly the right height for the valences, so I just overlapped them with it. The valence is held in place with a pair of L-shaped brass corner reinforcements, one each at the top and bottom, screwed into the side of the wire chase and the back of the valence:

Just barely visible in the photo is the saw cut I made in the wire chase cover panel - this was necessary to allow the cover panel to be removed without having to remove the valances. With the cut 1/2" up behind the valances, it is invisible but allows the cover to be slid down and then removed. (The wire chase was the very first carpentry project I did on Eolian, way back in 1998.)

At the over-sink cabinet I was less fortunate - I was not able to find flat corner reinforcements in brass, so I had to settle for stainless, which is much harder to work with. By cutting and bending, I laboriously fabricated these little brackets with the tools I had onboard:

They work like this to support the valances with screws driven up into the bottom of the cabinet:

So here's what it looks like with everything up:

I still need to take the valances down and route the edges, sand, and varnish them. And while they are down, they'll get a 2" wide strip of 1/2" white MDF attached to the back for stiffening. And then the pièce de résistance: warm white LED strip lites will go on top of the MDF to create some indirect mood lighting:

It's funny, isn't it? How if you look at something long enough, it becomes invisible. Even if it is surpassingly ugly, you eventually cease to see it.

Eolian's blinds are a case in point. Having blinds is a neat idea - even neater, these were custom made for the windows. And the installer made a good materials choice, with plastic louvers instead of metal ones. But unfortunately he did a pretty poor job aesthetically. Covering the blinds with valances has been on the list since, well since we got Eolian.

First, it was necessary to procure the materials for the valances: six pieces of teak, 4' x 4" x 1/2". Then there was a lot of thinking. I had two conflicting design criteria:

- There should be no visible screws

- The valances should be removable for full access to the blinds and windows

- Where the valances met the over-sink cabinet

- Where the valances met the wire chase coming up from the nav station

- Where the valance terminates against the wall behind the nav station

- Everywhere else

Next, I epoxied blocks to the backs of the valances. Then I drilled pilot holes up thru the blocks and into the mount points. Screws hold the valances in place - accessible but not visible. (Note: when gluing teak, always wipe it down carefully ahead of time with acetone to remove the waxy teak oils from the surface.)

|

| Invisible mounting #1 |

Next, at the nav station wire chase. The wire chase was (amazingly) exactly the right height for the valences, so I just overlapped them with it. The valence is held in place with a pair of L-shaped brass corner reinforcements, one each at the top and bottom, screwed into the side of the wire chase and the back of the valence:

|

| Invisible mounting #2 |

Just barely visible in the photo is the saw cut I made in the wire chase cover panel - this was necessary to allow the cover panel to be removed without having to remove the valances. With the cut 1/2" up behind the valances, it is invisible but allows the cover to be slid down and then removed. (The wire chase was the very first carpentry project I did on Eolian, way back in 1998.)

At the over-sink cabinet I was less fortunate - I was not able to find flat corner reinforcements in brass, so I had to settle for stainless, which is much harder to work with. By cutting and bending, I laboriously fabricated these little brackets with the tools I had onboard:

They work like this to support the valances with screws driven up into the bottom of the cabinet:

|

| (Almost) invisible mounting #3 |

So here's what it looks like with everything up:

I still need to take the valances down and route the edges, sand, and varnish them. And while they are down, they'll get a 2" wide strip of 1/2" white MDF attached to the back for stiffening. And then the pièce de résistance: warm white LED strip lites will go on top of the MDF to create some indirect mood lighting:

Tuesday, July 1, 2014

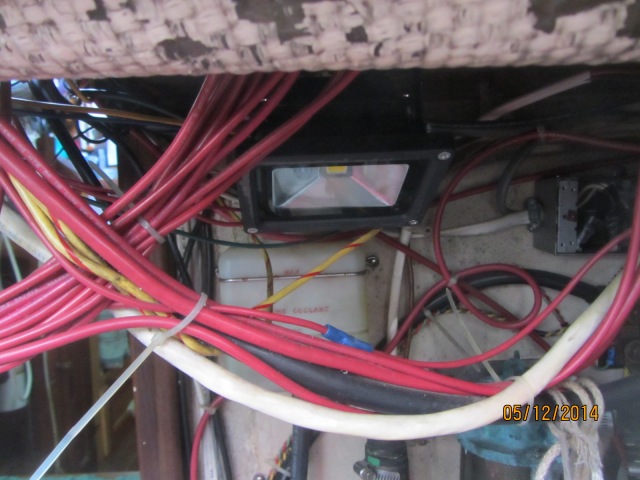

Wiring

Getting electrons to go where you want them to go (without any leakage!) is always a problem on a boat. And you want the wiring to be neat and concealed as much as possible. Steve deals with several wiring issues aboard s/v Siempre Sabado...

The next project I tackled was changing the light in the engine room. The old light had three problems:

I even went so far as to mount the switch in the cabin right next to the engine room door so we can tell at a glance if the light is on or off. Pretty sure it’s going to make things down below much easier.

The final thing I accomplished since last time is that I moved the stern navigation light. It’s always been on a little platform that was built as part of the stainless steel hoop that anchors the backstay. That was ok until we added our Cape Horn windvane. Now the bright LED sternlight reflects off the stainless steel of the windvane and ruins one’s night vision when looking aft. I decided to move the light up to the boom gallows.

I started by removing the light and fishing out the wire that fed it. Looked like there would be enough wire to run to the new location. I would have liked to have made this run without any breaks but that would make the job MUCH harder. First, I’d need one of these for running the wire through the inside of the bulwarks. Even if I’d had one, if I ran the wire through it and then it turned out that it wasn’t quite long enough, I’d have to make a splice in an area prone to getting very wet. What I did have on board were a couple of these, albeit 2-pronged ones:

So, I drilled a hole in the bulwark and then ran the old wire to the female end and mounted it on the inside of the bulwark just aft of the boom gallows.

As it turned out, the wire wasn’t quite long enough to make it to the light but, I really wanted to use it as it was much better wire than anything else I had onboard. So, I just moved the stern light a wee bit to starboard.

Once again, the toughest part of the job was getting the wire down through the boom gallows stanchion. I drilled an entry hole to feed it in but, naturally, it wouldn’t go. Tried using the stiffer wire and it kept getting hung up as well. Ended up removing the gallows so I could see feed the stiff wire straight down the pipe. It still got hung up a few times. On what, I do not know. But, eventually I got it through and could then use it to pull the electrical wires down to where they would feed out the open bottom of the stanchion.

That’s about my last pre-haulout job. I do think I’ll remove the dodger so I can see better when I motor over to the haulout dock but that’s about all. Don’t want to start stashing stuff below until I’m sure I won’t have to access the space underneath and I won’t know that until I’m in the yard doing all the jobs necessary before storing the old girl for a year or more.

All in all, the jobs have gone smoother than I had anticipated. Better that than the reverse. Now, if the yard jobs will just go as smoothly.

Since the last blog, I’ve run the wires for the outside stereo speakers. I haven’t actually mounted the speakers because I can’t seem to find the stainless steel u-bolts I brought back from the States. They’ve got to be here somewhere but I don’t know where. I’m also missing a couple of other small items. They’re probably all in the same bag somewhere. Wish I knew where. But, no matter because I’d no sooner get the speakers mounted than I’d have to remove them when we store the boat.

Mounting the speakers consisted of

- figuring out where to put them,

- figuring out how to run the wire inconspicuously,

- running the wire.

First, where to put them. The W28 companionway is not centered on the cabin making symmetrical mounting problematic.

If things were symmetric I could just mount the speakers on the cabin top on either side of the companionway. Be a piece of cake to run the wires then, just drill a hole under each speaker, run the wire out and seal the hole. But, on the port side there is almost no room outboard of the companionway at all so that idea is out. My next thought, and the one I went with, was to mount them on the forward dodger supports (thus the need for u-bolts). The speakers are kind of big but they’ll go there just fine. So, how to get the wire to them. The easiest way would be to run it along the dodger frame and just zip-tie the wire to the frame. But this goes contrary to Lulu’s wish to “make it pretty”. I could maybe run the wire inside the tubing, which is what I ended up doing. I pulled the dodger off and took the forward bow off the frame so I could set it down on deck for drilling. I drilled a hole near where the bow meets the aft bow. This would be the entry point for both wires. Then I drilled exit holes where the speakers were to be mounted. I tried pushing a piece of speaker wire through from the exit hole to the entrance hole but it inevitably ran into something inside that stopped it. Other than the nice smooth curve of the tube, I can’t imagine what there is inside that would stop the wire’s progress. Well, no matter, I just fed a piece of stiff wire through from the entry hole and then fished it out the exit hole where I twisted and taped it to the speaker wire. Then it as a simple thing to just pull the stiff wire back, pulling the speaker wire with it.

Then I put some anti-chafe gear (aka electrical tape) around the wire to protect it and tied a knot in it to keep it from getting pulled inside. Hopefully that knot won’t slow the music down and make it sound like a 33-1/3 RPM record playing at 30 RPM.

And, the final product, minus the speakers:

That’s a reasonably neat installation, isn’t it?

A close-up of the wire exiting the cabin. I used butyl tape to seal the hole:

Man! These are all so dark. Wish I’d discovered the camera setting sooner.

The next project I tackled was changing the light in the engine room. The old light had three problems:

- It was just a standard ceiling dome fixture with an incandescent bulb which didn’t shed light on all the places it needed to,

- Its switch was on the fixture itself which was in the engine room (duh). On several occasions, I’ve closed up the engine room with the light still on and didn’t know it. This happened recently when we were anchoring a lot. I was watching the meter panel and noticed that it seemed like we’d be using a significant amount of amps when nothing seemed to be on. This went on for a couple of days before I decided to check the engine room. Sure enough, the light was on. This speaks well of our new solar panels as they managed to keep up anyway. and

- The bulb in the existing light fixture is burned out. After reading this episode of Cunning Little Plan, I decided that I NEEDED lights like Mike bought. I bought three and have now installed one.

|

| Maybe now I’ll be able to actually see my dipstick. |

|

Add some ribbon lights above to send light into the shadowed areas and I could probably perform surgery in the engine room.

|

I started by removing the light and fishing out the wire that fed it. Looked like there would be enough wire to run to the new location. I would have liked to have made this run without any breaks but that would make the job MUCH harder. First, I’d need one of these for running the wire through the inside of the bulwarks. Even if I’d had one, if I ran the wire through it and then it turned out that it wasn’t quite long enough, I’d have to make a splice in an area prone to getting very wet. What I did have on board were a couple of these, albeit 2-pronged ones:

So, I drilled a hole in the bulwark and then ran the old wire to the female end and mounted it on the inside of the bulwark just aft of the boom gallows.

As it turned out, the wire wasn’t quite long enough to make it to the light but, I really wanted to use it as it was much better wire than anything else I had onboard. So, I just moved the stern light a wee bit to starboard.

Once again, the toughest part of the job was getting the wire down through the boom gallows stanchion. I drilled an entry hole to feed it in but, naturally, it wouldn’t go. Tried using the stiffer wire and it kept getting hung up as well. Ended up removing the gallows so I could see feed the stiff wire straight down the pipe. It still got hung up a few times. On what, I do not know. But, eventually I got it through and could then use it to pull the electrical wires down to where they would feed out the open bottom of the stanchion.

That’s about my last pre-haulout job. I do think I’ll remove the dodger so I can see better when I motor over to the haulout dock but that’s about all. Don’t want to start stashing stuff below until I’m sure I won’t have to access the space underneath and I won’t know that until I’m in the yard doing all the jobs necessary before storing the old girl for a year or more.

All in all, the jobs have gone smoother than I had anticipated. Better that than the reverse. Now, if the yard jobs will just go as smoothly.