I hope you'll forgive a brief hiatus here, while we celebrate Christmas in a place without Internet (posting this with my phone).

Merry Christmas and fair winds to all!

Bob & Jane

Life aboard is living large, in a small space. Every boat owner has found ways to make life in that small space easier, more comfortable, more convenient. The idea behind this site is to provide a place where these ideas can be shared amongst the boating community. To participate, send your contribution to SmallBoatProjects at gmail dot com.

Pages

▼

Sunday, December 23, 2012

Tuesday, December 18, 2012

Spice Rack

Over at Sail Delmarva, see Drew's take on storage of spices in the galley, and on making optimal use of the limited storage space on a boat:

PDQ 32s factory equipped with Dometic dorm-style refrigerators are also equipped with a completely useless drawer to the right of the fridge. The openings are too small for medium adult hands to fully enter, severely limiting the size of objects that can be stored. Even spice bottles are too big, except for the smallest sizes. The drawer was deep--18 inches but only pulling out 8 inches--so any thing that did enter would slide to that back and never be seen again; remember, the openings won't admit a hand or wrist so you can't reach the back, even with a fork held by fingertip. The whole business is built of 1/2-inch thick lumber, reducing the 7 1/2-inch cut-out in the fiberglass to a mere 2 1/2-inch inside shelf width. Just pitiful. Down low, below the drawer, is a cubby hole that is handy enough for small items, in our case disposable table wear; I wanted to keep that, but I didn't want more cubby holes.

Though I could have scratch-built a replacement, matching the wood would be a challenge and I liked the outside look and fit. Instead, I took a few measurements and reasoned that it could be gutted, fitted with an improved drawer that would make a very usable spice rack, and that I could accomplish this in an evening.

The entire cabinet assembly is easily unscrewed and taken home, so that all work can be done in the shop. That helps. The drawer facing pops off easily with a few carefully applied hammer blows and a little wiggling with a wood chisel. Likewise, the stops in the back (to preventing the drawer from coming all the way out when pulled) popped right off. Both were easily cleaned of glue residue with a chisel.

I removed both sides of the drawer, leaving the top, bottom, front, and back untouched, with careful plunge cuts with a circular saw and some trimming with a saber saw. The sides are still attached to the shelves with a few spots of glue, but were pried out with very little effort. Likewise, without side support, the internal shelves were easily removed and discarded. The new plan called for only an upper and lower rather than the original overcrowded 3 shelf arrangement.

The new shelf is not centered; spice bottles come in 2 basic heights, so I made room accordingly.

I did not replace the original sides. The original drawer had ~5/8-inch clearance on each side, so I simply screwed new 1/4-inch birch ply sides to the outside, increasing the internal width of the shelf by 1-inch to 3 1/2 inches This is critical, as it makes the difference between a single row of bottles and a double row. I made the fiddles on the shelf a bit over 1/2 the height of the bottles to insure they cannot jump out in wild conditions, though they will simply end up in the large locker under the fridge if they do. With the larger cut-outs my hands fit easily. The corners of the cut-outs were made with hole saw and press (no center bit) and connected with a circular saw and saber saw and trimmed with a hand grinder. All of the screws are countersunk to avoid catching.

The original drawer did not pull out as far as it could; measurement showed that it could pull about 2 1/2 inches further without interference, so I repositioned the stops. This was easily done by extending the new sides back an additional 2 1/2" + 3/4" = 3 1/4" beyond the back of the drawer and attaching 3/4-inch cleats. Free additional opening space and less is lost in the depths.

Easy...ish and built from scraps. $4.65 for screws. I could have built it with hidden fasteners, but I liked the idea of being able to open it and change it, if I like. About 4 hours, but 3 of those were spend measuring an figuring. I could do a second in an hour. Isn't that typical?

More space, more function, no change in weight, and my wife is appreciative. I find the last of these most rewarding.

Thursday, December 13, 2012

Low-Buck Lighting Review: Old School Edition

Over at Dock Six, Brian does a study of traditional, really traditional cabin lighting. And not surprisingly, Brian does it low-buck style...

As prodigious as we are with rum consumption, we are as miserly with electrical power aboard Whiskeyjack.

We light the cabin with battery powered LED lighting which consumes a relatively small amount of power compared to traditional Edison-style bulbs, but LED lights have drawbacks not considered when we installed them.

For example, insects like them.

A lot.

In fact, a lot of little bugs like LED lights a lot.

(Yes, we have screened hatches, but that only keeps insects out that are already out when the hatches are closed- those insects that are in when the doors close remain in, swarming around the lights. It's sort of like a dance club at last call.... in reverse.)

The ambiance factor, or lack thereof, with most LED lighting is also not inconsiderable. The LED lights aboard bounce off the fiberglass overhead and fore and aft bulkheads, casting a dental-office style glare, hardly inducing one to curl up with the latest copy of Good Old Boat.

There are certainly alternative colour LED bulbs, in warmer and fuzzier hues, but retrofitting all of the panel-wired fixtures below deck is not an inconsiderable expense, and a project filled with trepidation. What if the bulbs we feel are bright yet warm, clear yet cozy in the store/at the show/ in the display/whatever feel different in the confines of our cabin? Most vendors have a "no return" policy on electrical stock, bulbs included, so I envision ending up with hundreds of dollars of perfectly good yet completely unacceptable lightbulbs occupying valuableboozespares stowage real estate.

And there is still going to be the infuriating infernal interior insect infestation in orbit around the aforementioned illumination.

So, it was time to suss out some alternatives.

image courtesy of amazon.com

Candles cast a warm glow, but lend little illumination, as evidenced by the small votive candle in the cockpit below. An advantage over fixed-site lighting, however, is the convenience of being able to move light from deck to Dock to cabin to cockpit. More flexibility in lighting means less lighting required on board, and less storage space dedicated to redundant illumination.

It got me thinking, though. Why not try going old school? We decided to explore the world of lanterns.

Traditional ship's lanterns....

... seem to fall into two categories:

Is there an alternative?

- More expensive than electrical light, more elegant, well built and provide adequate light, and

- More expensive than electrical light, more elegant, really poorly built and provide inadequate light

We decided to find out.

Low-buck style.

Here's the parameters:

Go.

- Non-electric light suitable for reading/working in the cabin.

- Portable- usable in cockpit, cabin, on deck or on Dock.

- Unattractive to insects

- Under $25.

First stop, Canadian Tire , where, for nearabout $17, I purchased a World Famous hurricane lantern, not exactly as shown, below.

When I purchased the lantern, it had a "World Famous" label attached to the chimney, which peeled off and fluttered to the floor when the lantern was removed from it's cellophane wrapping. The lackadaisical label was an accurate indicator of the quality of the lantern to which it was formerly attached. The price was cheap, and the product lived up to the price. Included was a business card-sized slip of paper with filling and lighting instructions printed in smudgy 6 point type. The lantern itself is about 12" tall, with a base diameter of about 5". The fit and finish appeared sloppy, an impression which was dramatically reinforced later.

Next, we paid a visit to our good friends at Lee Valley Tools and traded $19.95 for a Dietz "No. 80" hurricane lamp.

Wow. What a difference $3 makes. The Dietz lantern came in an honest-to-goodness box with the globe wrapped for protection. Included were lighting and cleaning instructions, wick trimming info and a short but succinct trouble-shooting guide. Compared to the World Famous lantern, No. 80 felt huge, standing 15" high with an 8" wide footprint. Fit and finish was better than expected, with decent plating on the burner, bails, globe plate and tank cap.

Price winner: World Famous

First Impression winner: Dietz No. 80

With the contestants chosen, it was time to get them ready for use. Both lanterns are kerosene fueled, so after a perusal of the filling directions, the lanterns were placed on the table and loaded with kerosene...

...sonofabitch!!!!!...

The World Famous lantern's instruction slip included the cryptic phrase "Do not fill tank more than half" There was no explanation for this fortune-cookieish bit of advice, and also no instruction on how one determines when the lantern is half full- there are no "fill to here" markings, and the small fill port is completely obscured by the spout of the kerosene container providing sustenance, so trying to eyeball the level doesn't work. So, in typical Dock Six fashion, I guessed.

And overshot the mark.

I discovered this fact when keroseneleakedSTREAMED out of the tank, not from the fill port, but from the tank itself. It turns out the tank has a large hole where each of the legs that hold the chimney are attached. I cleaned up the kerosene from the table top, aired out the cabin and turned to fueling No. 80.

Which was accomplished in an incident-free fashion.

Fueling Winner: Dietz No.80

With the candidates ready for action, it was time for the illumination elimination round. Time to introduce the incumbent to the festivities, the $2 LED lamp that hangs over the table, affectionately known as the " UFO Light"

Here's UFO in action:

Here is how a copy of Good Old Boat looks under the light cast by UFO. Lots of illumination, but lots of glare as well.

That is the current cabin lighting standard aboard. Let's see how our competitors compare.

With some fiddling, with both hands as the globe refused to stay raised thanks to the poor fit of the lifting bail, World Famous was persuaded to light, and with further fiddling, encouraged not to smoke (at least not until it's 18 years old and/or no longer resides in our house).

Illumination was provided, but, like every other aspect of this lamp, it was disappointing.

One can see that there is a magazine in front of them, one can discern that there are photos, one can read the title, but beyond that, gathering information from the page is a struggle. Illumination was spotty, with shadows and flickers

I briefly suspended the test to trim the flickering wick and wash the soot off the globe, hoping to increase the output.

The result?

Um, yeah.... no.

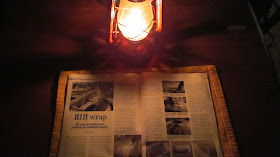

Right then, let's see what No. 80 brings to the table.

Definitely easier to light, requiring only one hand. Lift the globe, lock the bail, set the wick, strike a match, trim the wick, lower the globe, done.

The result?

Usable illumination. Warmer, brighter, over a larger area with no shadows or flickering. Not nearly as bright as UFO but easier on the eyes and bug-free!

Illumination winner: Dietz No. 80

Further testing in the cockpit on our last sail of the season earned compliments from Jack and Melanie on how well No.80 lit the cockpit, with none of the breeze induced flickering and relighting as was often the case with citronella candles, and no wax on the cockpit sole.

I think we might have a winner, with some improvement to the plan. A second lantern is needed to fully light the cabin, and lighting the v-berth with a lantern this size isn't gonna work, so there is no choice in retaining some LED lighting.

The "cozy" factor is not to be underestimated, however, and the consistent response is how much "nicer" the lantern light feels compared to the electric alternative.

We're gonna give it a long term test next season, and we'll let you know how it goes.

Tuesday, December 11, 2012

Making Baggywrinkle

In addition to its time-proven effectiveness at preventing chafe, there isn't a much better way to make your boat look "salty" than to install some baggywrinkle. And Steve and Lulu on s/v Siempre Sabado show us how easy it is to make:

First off, the basic instructions came from one of our favorite books: “The Arts of the Sailor” by Hervey Garrett Smith.

You can also find the directions (including Hervey’s) on-line by googling “making baggywrinkle”. But, it’s a lot more fun to have a copy of Hervey’s book onboard.

First you have to collect a whole bunch of 5-6″ pieces of line that’s not good for much of anything else. We used the cut-off ends of the 3/4″ manila that we made our fenders out of. Lulu unlayed the line and then divided each strand into separate yarns.

Then you double a long piece of nylon line to use as a core and fasten it between two anchors. To get an idea of how long the core needs to be, a 4′ long piece of baggywrinkle, wrapped around a 1/4″ shroud, will end up about 1′ long.

Now you need to start making the individual thrums or rovings. Pass the yarn under the core piece:

And then push it up against the pieces you’ve already done:

Pass the ends around the outside of the core and down through the middle.

Then, you just tie one end on to the shroud and wrap the baggywrinkle around and around until you end up with a “brush”. Tie off the ends. Secure the knot with rigging tape if you’re insecure about the security of your knotwork, and then stand back and wait for everyone to ask, “Where’d you get those?”

There you have it.

Thursday, December 6, 2012

Aluminum tape: its time has come

What keeps a tape from being permanent? Two things:

The substrate is actually metal - it's aluminum - thin enough to stretch a little and to easily conform to almost any shape. And because it is metal, no sunlight - zero sunlight - penetrates the substrate to attack the adhesive. The metal is polished and apparently anodized - it survives years of exposure to sea air without a blemish.

And the acrylic adhesive they put on this tape is some of the most aggressive I have seen. And because it is protected, it is as easy to remove tape that has been in place for years as it is to remove newly-applied tape - the adhesive does not get hard.

Here are a couple of examples where this marvelous stuff is in use on Eolian:

- The substrate does not survive contact with moisture or sunlight

- The adhesive fails, usually due to exposure to sunlight, and dries out or crumbles

|

| Look for it in the insulation aisle |

The substrate is actually metal - it's aluminum - thin enough to stretch a little and to easily conform to almost any shape. And because it is metal, no sunlight - zero sunlight - penetrates the substrate to attack the adhesive. The metal is polished and apparently anodized - it survives years of exposure to sea air without a blemish.

And the acrylic adhesive they put on this tape is some of the most aggressive I have seen. And because it is protected, it is as easy to remove tape that has been in place for years as it is to remove newly-applied tape - the adhesive does not get hard.

Here are a couple of examples where this marvelous stuff is in use on Eolian:

- Sealing the top of the mast boot. The tape adheres tenaciously to the mast, forming a permanent water-tite seal, and it conforms nicely in the task of overlapping the mast boot fabric. The hose clamp serves to mechanically hold the boot in place - not to create a seal.

- Sealing the joint where the two ends of the extrusion come together on our windows. When they came from the factory, there was an internal seal, but I had to destroy this to replace the glazing. The tape is a permanent cover for the joint.

-

Protecting the PVC used to make the new wind vane

Tuesday, December 4, 2012

A better spice solution?

Mike and Rebecca on s/v Zero to Cruising have a suggestion for spice stowage that just might catch on...

It's a great idea! The only thing I'd add is an additional label on the top of the containers, so they can be identified when they are packed in that too-small space you have reserved for spices...

Even though I have already devoted a couple of blog posts (1 and 2) to the subject of spice organization in the galley, you’d read here that neither of those ideas worked out so well for us. The solution illustrated below struck me as genius though. The plastic boxes originally contained Tic Tac candies and, in my opinion, are the perfect size for a boat. Maybe we should look for some of those when we head to downtown Port of Spain today?

By the way, relating to yesterday’s post, our vote for the island in the Windwards and Leewards with the largest number of good anchorages goes to… drum roll… Antigua! We’re definitely looking forward to visiting there again on our trip back north.

Thursday, November 29, 2012

Low-Buck Tools: 5 Minute Clamps

As usual, Brian over at Dock Six has a nifty idea. This one is for quick, easy, and multitudinous clamps. If you've ever done a stitch-'n-glue or a laminating project, you know you never have enough clamps...

As we transition from boating season to boatbuilding season, one realizes that one never has enough clamps. Further, if one is like your humble scribbler, one does not realize one is short of clamps until one runs out.

As the epoxy or glue is starting to set.

At midnight.

So, here's a quick and easy recipe for cheap gluing clamps. I'd like to take credit for this one, but I picked this up from Don Casey or WoodenBoat magazine or West System's Epoxyworks magazine. One of those smarter-than-me sources.

Pick up some ABS and/or PVC pipe in the diameter you like- 2", 4", 6", whatever. Hell, get a variety of diameters and wall thicknesses. $20 will buy you enough for 20-30 clamps.

Better yet, drive through a subdivision under construction with a six pack of cheap beer. Stop at a house with a plumber's truck out front. Offer to trade beer for pipe offcuts. You'll get lots, already cut to convenient lengths, and a hardworking guy gets beer, and less garbage goes to a landfill.

Win/win/win.

Take your pipe home, and split it down the middle. I set the fence on my table saw to the radius (half the diameter, for you non-math types. Diameter is the measurement across the center of the pipe, for you really non-math types) of the pipe, crank the blade up just high enough to cut through the wall of the tubing,

... and rip a split down the length of the tube.

On larger diameter tubes I cross cut the tube using my table saw. Set the fence to cut 1-2" wide slices of tube.

I cut smaller diameter tube on my miter saw, with a block of wood clamped as a stop at the desired thickness.

Sand any rough edges, and boom, you're done.

Thicker wall tube provides more clamping power. Thinner wall tubes are easier to manipulate single-handed.

Now go build something!

Tuesday, November 27, 2012

Salon Table Access

Too often, I find myself just living with problems - not even recognizing that they exist - endlessly banging myself on things, or struggling with storage. Drew, over at Sail Delmarva, demonstrates once again an uncanny knack for recognizing problems and then solving them.

While the salon table provides worthwhile storage volume, it has always been awkward to access. Something is always on the table; dining accessories, snacks and general stuff the forward end, and a DVD player is in permanent residence on the aft end. BTW, the flat screen hinges up and the Bose computer speakers speakers can really rock the boat.

I replaced the aft access lid with a hinged section. Just pine from retired shelving unit and a cast-off piano hinge. The finger holes for lifting were drilled about 1/2-inch deep with a forstner bit, which leaves a smooth, flat bottomed hole. If we like the functionality I may either stain it to match or slice the original board at the appropriate spot. So far, we like it; we can actually use these bins. Case in point: installing this project I found a book-on-disk that had been borrowed from the public library and long since paid for as lost.

As for the hinged flat screen and the forward section, those are described elsewhere, but they look like this...

and like this....

Now, to listen to that book-on-disk....

Tuesday, November 20, 2012

Battling clutter

Mike and Rebecca aboard s/v Zero to Cruising tackle clutter in a way that puts reading materials that are needed to hand out of the way, and yet keeps them easily accessible:

I live in a small boat and I hate clutter. Those two statements together almost guarantee that I will forever be stressed out because, with a small boat, there is not a ton of space to hide the misc. bits of stuff that we need to live with, aka clutter. For example, at this very moment, within arms reach of where I’m typing this post, there are five books and two Kindles, and that’s just reading material! No wonder we’re always looking for creative storage solutions.

Not too long ago I came up with a storage idea that I thought would work but because it involved sewing, we put it onto the list of tasks to do when we next broke out the sewing machine. Getting the sewing machine all set up for just one little job is a PITA. Yesterday, and the day prior, was such a time though. After describing to Rebecca what I wanted, and sketching it out on a piece of paper along with some rough dimensions, she set to work. Fortunately, we still have quite a bit of Sunbrella remaining from the supply we purchased when we were back in Annapolis.

As with many boat projects, the original design ended up being modified a few times over the course of construction but we’re pretty happy with the finished product. While I had originally intended to fasten the top edge with screws, down inside the lockers underneath the seat cushions, I determined that if a block of wood was sewn into the top (we actually used a chunk of plastic material that we had on board), it would act as a stopper so that when the locker’s lid was closed overtop of it, it would remain in place. In my mind this is a big improvement as, while it is still secure, it can be removed easily and didn’t require any more holes to be drilled in the boat. Perfect!

Tuesday, November 13, 2012

Half forgotten objects

Over at Sail Delmarva, Drew has been busy with his wood working tools again...

Certain objects cry "nautical" from the first glance: A wooden ship's wheel, a brass lantern, wooden shell blocks. Not practical, though, and cliche on a modern boat. There are items we accept as functional and usual: a stitching palm, a life ring with the yacht's name, coach whipping on the wheel or tiller. And then there are half forgotten objects with real utility, in my opinion at least, underutilized.

The Finishing Bench. Still used by traditional sailmakers, a simple bench holds the implements used for roping, adding a grommet, or mending. I made this one about 5 years ago from nothing but scraps and a little varnish, a very pleasant way to spend a few winter evenings. Mostly it sits by my favorite chair, holding magazines and what ever books I'm reading, but my stitching tools and materials are ever present on the far end. Yes, I catch a pant leg on the bench hooks now and then. But whenever sail work is required I carry it out in the front yard where it serves its traditional purpose very well. Smaller projects get sewn up right in my chair, reaching back for traditional tools and materials that are kept conveniently at hand.

No directions. I just followed an old illustration and fit it to the scraps I had. I suppose they were generally built that way, from bits and pieces.

- Cleats on the underside reinforce the legs.

- Numerous holes and vertical dowels on the cutting block secure spools of thread or hold knives and fids. Some holes only go part way through, holding needles and small things.

- Dowels angled just above horizontal on the cutting block end hold scissors, palms, webbing, thread, and a small ditty bag.

- Bench hooks need to be sharp, and it is handy to have 2 different lengths. These were bent from steel tent skewers.

That first step is about 30 inches.Sea Chest. Although my boat has some cavernous lockers under the bunks and salon seating, there are never enough small lockers handy in the staterooms. Additionally, getting into the bunk is rather athletic, as the bunks are high and without steps. Additionally, a seating platform with storage blocks the way to the bunk, and it is at an unfortunately awkward height, far too high for putting on shoes. At first I built stools, but they were really too small and too single purpose. A small sea chest, fit to the space, is the perfect answer.

Though I didn't take any pictures of the construction process, anyone with the carpentry skills to make a box should be able to do just as well.

- Traditionally these were painted a muted color and only the inside of the lid would be decorated and bright. Paint best withstood hard knocks, and the interior decoration reminded the sailor that his chest was the one thing on board that was his. However, my wife liked it varnished--all of the reproduction examples I showed her on-line were varnished--and it works, I think. Perhaps I'll paint it later; if so, going from varnish to paint is more reasonable than the reverse process. Because I originally planned for paint, I made no special effort to hide fasteners; I focused on building it strong enough for regular use as a step. I think I like the utilitarian look.

- Strap hinges are traditional, but a piano hinge fits better, and I had a cut-off. I cut a recess for the hinge so that it closes perfectly, with no need for a chain and with all of the weight transfer directly to the sides.

- Be mindful of protruding hardware. While a few scratches didn't matter on a whaling ship, they do to us. For example, the handles were traditionally attached with exposed rivets, but I substituted counter sunk brass bolts. Same on the inside; nothing to snag on clothes. I smoothed all interior hardware with a Dremel tool.

- Side Relief. A characteristic of sea chests is that the sides lean inwards. The practical reasons for this only became obvious as I measured the intended space: if slammed against a bulkhead (ships move) the lid will still open and the handles are still accessible; they better resist tipping; there is less binding when push into or pulled from a tight space. The trim strip on the bottom also helps; it takes a beating and thus should secured with screws, not brads.

- Rope handles. Mine are boring. Starting with a bit of old 3/4-inch 3-strand line, I placed 2 whippings about 9 inches apart, unlaid both ends for about 3 inches, and pinched the strands between handle blocks and the chest sides (I had drilled 1/2-inch holes with the handle blocks clamped together, making half-round groves for each of the three strands), trimming the excess. Tape held the strands in in the groves while the bolts were tightened. Strong and compact enough to fit the narrow space I had to work with, but not fancy; I lack the marlinspike skills to do a proper job. However, even simple rope handles are strong, comfortable, and non-scratching.

- Square the sides up on a flat floor before screwing them together; you don't want a rocker. Likewise, true the lid to the top; otherwise the hinges will work loose in time. When working with scraps, never presume anything to be square or true.

- No latch. Didn't see the need for my purposes

- Hold down. In the stern of a catamaran the motion is never lively enough for the chest to move, but I can certainly imagine boats and places where this is not true.

Something more traditional

All from scraps. In the first example, I used a few boards that were left in the basement by the previous homeowner and a bit of left over shelf. The dowel was from a discarded seasonal decoration. In the second example, I salvaged a neighbor's old garage shelves and some line left over from a Practical Sailor testing article--the stuff we found under a dock and cleaned. The brass bolts--16 x #8 x 1 1/2"--were also left overs from a writing project--laboratory corrosion testing of gasoline anti-corrosion additives. I think that is the way these sailor's tools would have been made, from the bits and pieces. The finishing bench was free, the sea chest a $2.45 project (a bit of 1/4-inch plywood for the floor--I wanted something lighter than the scrap I had on hand). Very affordable.

Tuesday, November 6, 2012

New cabin lights

Please welcome new contributors Nate and Natalie aboard s/v Astraea! We join them mid-refit of their Cheoy Lee 41 - there have been a lot of projects there, but most have been too major to qualify as "small" boat projects. But this one is a perfect fit...

A few weeks ago I added two new lights inside the cabin. One is centerline above the salon between the head and galley, and the other is on the aft port side over the top loading freezer in the galley. I bought the two new lights at the San Diego Marine Exchange and installed them in a day.

The lights are seven inches in diameter and need a 1/2 inch thick mounting base to keep the lights off the overhead and allow for flush mounting when the headliner is installed. I cut two new eight inch square bases out of 1/2 inch thick StarBoard, a sturdy plastic board I had left over from the wet exhaust project. There is an inch wide gap cut in one side to the middle to conceal the wiring.

The terminal block is installed on the white StarBoard base with the teak light mounting

It took a full day’s work to cut the bases and install all the wiring. Having the new lights really brightens up the interior. Because they’re LED, I can have all the cabin lights on and use less electricity than one of the old incandescent bulbs!