[Editor's note: Not sure that the 3M 4000 - or any adhesive for that matter - would stick to polyethylene]

I have two port holes in the side of the cockpit well (near the floor), which we keep open all the time. We place in the port holes, these snap in bug screens; but as you can see, from the picture to the left, some of the plastic has broken off. It is also broken in a couple of other places not visible in the photo. These bug screens are 1985 vintage and have just deteriorated through use and I suspect UV damage. Also, these sit around shoe level when sitting in the cockpit, and occasionally get popped out by an accidental heel kick.

Wooden Template

In reconstructing these, I first made a wooden template suitable for a router. I used MDF (medium density fibreboard). Next I procured some PVC board, which when doubling the thickness of the PVC board, was just a few millimeters thicker than my old bug screen. I used PVC, but could just as easily have worked with Polyethylene plastic board.

Next I cut out of the PVC board, four rough finished frames which were about 5-10mm wider than my template. You might notice that my template has a wider surface than the original bug screen. This was to give it some added strength and make it easier to place the bug mesh between the two PVC cutouts.

Routering

I used double sided sellotape to secure the template to the rough cutouts and then routed the remainder of the PVC off to the finished template. Each one was done in turn.

Then because my template wasn't exactly symmetrical I matched two pairs so that all corners lined up perfectly.

Mesh glued and trimmed

I lay one side of my PVC cutout down and placed a small bead of 3M 4000 deck caulking compound in the centre of the flat surface. Then I placed my bug screen mesh (Nylon I think) over the top off this, then spread the 4000 over the mesh so that it was in the middle and not near the edges, and sat level with the mesh and not proud. Final tension was then applied to the mesh and it was allowed to set up. This was to act as a "glue" so I could the trim the mesh about 1mm in from the outer edge after it had set up.

4000 applied before 2nd side attached

Next application of 4000 was applied in a thin layer over the mesh, but not approaching the inside edge by about 5mm. If the 4000 is squeezed out to the inside and over the mesh, the job looks "ugly" and once set is hard to remove from the mesh without damaging it.

Glass over top for glue to set

Finally the other side was applied, being careful that both PVC cutouts lined up perfectly. The PVC was pressed down from the inside edge to the outside, squeezing out any excess 4000. A plate of glass was applied over the two pieces and allowed to set up.

After it has set up, a sharp craft knife was used to trim the excess off, on the outside edge.

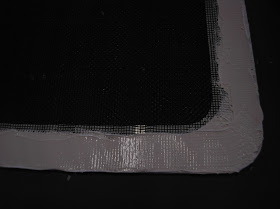

Finished product

The finished product to the left. It's both flexible and hardy. Should last several years. But, if you need to change the mesh, just slip a blade between the two sections to break the bond. Clean up and repeat the process for new mesh.

What am I going to secure it with in the port hole? Probably "blue tack"; but one could use a double sided foam tape, like they use to secure mirrors on walls.

Don't try to do the gluing in one step with the mesh. I tried and it was very difficult to have both PVC pieces line up perfectly. Also when trimming the mesh off, you could still see the mesh on the outer edge and it looked "ugly". A much better finish, if you glue the mesh to one piece first; have it set up, and trim the mesh back from the out edge. Then, when trimming the final outer edge of 4000 is done, a nice white finish is all you see. So, in essence, what you see here is a bug screen that has had the mesh replaced once because I didn't do it right first time. Cost $30 for the PVC 1 square meter sheet; and $7 for the mesh.

Life aboard is living large, in a small space. Every boat owner has found ways to make life in that small space easier, more comfortable, more convenient. The idea behind this site is to provide a place where these ideas can be shared amongst the boating community. To participate, send your contribution to SmallBoatProjects at gmail dot com.

Pages

▼

Tuesday, October 30, 2012

It may not seem like the right time of year to do a project regarding bug screens... in the Northern hemisphere. But Paul on s/v Solace is located in the Southern hemisphere, where this a good and proper project for this time of year - Making replacement bug screens:

Thursday, October 25, 2012

Sometimes it's the little things

Over on s/v C'est la Vie Jeff has been working on a big project: refurbishing his engine room. Now this certainly does not qualify as a "small" boat project. But in the midst of this, he has found one of those small things that can be more important than the big ones.

One of the few items remaining in C'est la Vie's engine compartment is the drive shaft. The drive shaft is a solid stainless steel rod that connects the engine inside the boat to the prop outside the boat.Inspecting and replacing hose clamps is a "small" boat project we should all perform, annually at the least.

C'est la Vie's shaft and shaft seal were replaced in 2007 Traveling from the prop towards the engine, the point where the shaft passes through the hull it is supported by shaft log. The log is a bronze tube with rubber bushings. The log relies on water from outside the hull to serves as a lubricate thus reducing wear and friction. Directly forward of the log is our shaft seal. The shaft seal allows the shaft to spin freely yet prevents water from entering the boat. In 2007, we replaced the shaft, shaft log, and the shaft seal (here is a link to the photo album - Replace Shaft, Log, and Seal - fall 07)

During the 2007 project, we purchased a PYI-PSS shaft seal and had the boat yard complete the installation work. The shaft seal uses a rubber bellows as a spring to press a carbon flange against a spinning stainless steel rotor. The carbon flange and stainless steel rotor are very smooth and when pressed together create a water proof seal. As with any hole in the hull of the boat a failure of this system can cause the boat to sink.

the newly installed shaft seal - Fall 2007

Since all the components of the shaft system were new in 2007, I left them in place and did not intend to replace any parts. My experience over the weekend has me questioning this decision.

C'est la Vie's Shaft Seal - Sept 30, 2012

While sanding between coats of primer in the bilge, I noticed a paint drip on the aft most of the shaft seal's four hose clamps. Using a scotch bite scrubbing pad, I reached back to remove the paint drip. Instantly the hose clamp broke in my hands.

the stainless steel hose clamp that broke in my hands after 5 years of

service on our shaft seal.

Alarmed I grabbed a nut tool and attempted to loosen the other hose clamps for an inspection. The very next hose clamp I touched, the forward most clamp, broke as I torqued on the hex head. Yikes! Failure of these clamps can sink the boat. The clamps used on shaft seal were provided by the manufacturer, but are not of the quality I expect for critical through hull fittings. Not all hose clamps are created equal.

Without a doubt all hose clamps on board a boat should be stainless steel, but even among stainless clamps there is a broad spectrum of quality. Clamps used in critical areas (i.e. through hull fittings, engine coolant lines, engine exhaust lines, black water systems, etc.) must be ABYC approved 316 stainless steel with a non-perforated band.

an ABYC approved 316 SS hose clamp with a non-perforated bans will replace

the bands on our shaft seal.

How does one identify the various quality of clamps? The easiest test is to run a magnet across all hose clamps on the boat. If the magnet is attracted to the clamp then the clamp contains ferrous metal that will easily rust. Any clamp attracted to a magnet needs to be kicked off the boat ASAP. I keep a magnet in my tool box expressly for testing hose clamps, bolts, screws, etc. If any of these items do not pass the magnet test then off they go.

Hose clamps that will pass the magnet test are appropriate for non-critical boat systems (i.e. tank vent lines, fresh water plumbing, etc.). If the clamp is destined for a system that is considered critical then it must pass two additional tests. First is the band non-perforated? A non perforated band is stronger, better resists rust, and provides more uniform pressure around a hose. Secondly the hex head on the clamp must be 7mm.

I'm unsure if the 7mm hex head is a brand specific standard or if it is set by the ABYC. All high quality AWAB Hose clamps have a 7mm head so I look to this as an identifying feature of high quality clamps.

If your using the 7mm head as standard of quality then I recommend purchasing a flexible shaft 7mm nut tool to compliment the clamps.

It is worth noting an exception to my hose clamp rant. As hose diameter increases to 2" or greater and/or if the hose has a wire for additional strength (e.g. engine exhaust systems), then t-bolt hose clamps are recommended due to their ability to provide increase pressure on the hose.

Tuesday, October 23, 2012

A custom anchor platform

Because of their shape, Danforth anchors are difficult to stow on a "standard" bow roller. Rick dealt with this problem on s/v Cay of Sea by making his own anchor platform, specifically designed to work with the Danforth. Tho the project below does not show the design and construction of the platform directly, I think the pictures give enough detail to allow one to construct their own anchor platform:

A year ago last month, I fabricated and installed an anchor platform for Cay of Sea. This took quite a while, because the platform had to accommodate a danforth-style hook – not the easiest anchor to fit to a platform. Also, it was a “custom” fabrication, so there was a great deal of measuring, marking, trimming, fitting, refitting, remarking, designing, redesigning – you get the idea. It was a lot of fussy work, but the result was a great improvement for stowing and handling the ground tackle.

This is the way it looked this spring before the finish failed. Compare with the following images:

Failed Finish

Close-up of failed varnish and darkened grain

So maybe this doesn’t look to alarming to you, but considering that it is made of red oak, taking action is indicated sooner than later. Red oak is a lovely dense, hard wood that is tough. The problem with it is that it is rot-prone. I knew that when I used it to build the platform, but I used it anyway because it was readily available and reasonably cheap. I reasoned that if I kept it protected with epoxy and varnish, it would do fine.And it would have done fine, if I had kept up with it this year. However, I got in a hurry last fall to use it, and only put on 3-4 coats of cheap varnish, promising myself that I would do a better job soon. . . Soon is relative, you know. I should have re-varnished this spring with the good stuff, but I didn’t. Subsequently, here we are in mid-fall, and I’ve got to redo the finish correctly.

I was also dismayed to find out that the fender washers I used weren’t stainless, or were an inferior grade of stainless, and they rusted. I know I chose them from the stainless bin, but sometimes fasteners and hardware gets shifted about. When I reinstall that platform, I’ll be sure to use high quality stainless fender washers.

After removing the platform, I was happy to see that my sealant (Boatlife caulk) did a great job of keeping the water out of the boat and out of the bolt holes. I sealed the deck holes with epoxy last fall, but did not pot the holes and re-drill. I intend to do that while the platform is off too.

So the first step was to remove/strip all the finish off. I used Strypeez paint remover – the really thick stuff, and it did a really good job. It was in the 50s yesterday while I was using it, so it worked a little more slowly, but it did the job.

Strypeez slathered all over

After removing the finish, I used oxalic acid to bleach the dark lines out of the wood, and lighten it over all. Three heaping tablespoons in a quart of hot water made a very strong solution.

I wiped the piece with solvent, then mixed my epoxy resin, and here I may have a glitch. My container of West System resin pulled air with the second pump, and I got an imprecise measure of resin. I pumped in two pumps of catalyst anyway, and hope the ratio is nearly correct. If it isn’t, it won’t cure properly – I’ll know tomorrow morning if it cured. If it didn’t cure, I’ll have to strip it again and re-coat with a properly mixed ratio. Regardless, I’ll need more resin for subsequent coats, so there’s no great loss if I need to take an uncured coat off – just a bit of time.

And, I got a comment on my introductory post requesting a few more photos of the platform, so here they are:

Thursday, October 18, 2012

Making winterizing easier

Do you live in a climate where you need to winterize your boat? Thankfully, here in Seattle, if you live aboard winterizing is pretty much synonymous with addressing deck leaks. But if you do need to winterize, Drew over at Sail Delmarva has some suggestions to make this annual task easier...

I'm not clear why a boat made in Canada came without the most basic provisions for winterizing.

______________

The Head

Since I stay in the water all winter, I need to be able to winterize every hose. During the coldest weeks I flush with a weak glycol solution, so the down stream portions are no concern. I pump-out before it gets too cold for the stations to close and generally make it until they thaw. However, the suction side presents a problem. Additionally, I've had occasional trouble with sea grass fouling the intake valve on the head pump. Two years ago I installed a simple Y-strainer, which solved the clogging problem, but it was very difficult to clean; the lid would stick and the location and leverage were terrible. About a year ago I replaced the intake hose, upgraded the strainer (also a freebe) and moved it to a more convinient location in the holding tank compartment, and added a glycol addition fitting. No more clogs and 5-minute winterizing.

To winterize the sea cock side:

To winterize head side:

- Place the head pump in the locked position.

- Clean the strainer, if you think it's due.

- Open the sea cock.

- Open the blue valve and add ~ 1 quart of glycol from a jug on deck (it also has a drain valve).

- Close the sea cock.

Why red instead of pink? I use ethylene glycol (EG) antifreeze on the head system:

- Open the blue valve.

- Unlock the head pump and pump until you see red.

- Close the blue valve.

- I get it for free (we make it).

- The affect on the sewage plant is less than for propylene glycol (pink non-toxic, AKA PG) because less is needed (PG is less effective, on a percent basis) and they biodegrade at the same rate.

- Ethylene glycol is NOT more toxic to fish or the environment. It is only more toxic to mammals. Don't take my word for it--read the MSDSs.

- The head side is most certainly not potable!

- EG is less harmful to the hoses than PG. Just a little, but that is one of the reasons propylene glycol is not favored by automotive OEMs.

The Pressure System

Adding just a few valves made this into an easy one-gallon job. 15 minutes, tops.

Only non-toxic propylene glycol on the potable side, obviously.

- Pump the tank empty. Remove what remains by bailing with a cup or with a shop vac. No glycol in the tank.

- Close the valve to the left of the strainer.

- Open the valve to the right of the strainer and place the hose in a jug.

- Open every tap on the boat, both hot and cold, and let run until glycol comes out. Have a jug handy to catch any extra.

- Once the jug runs empty (most likely before you are finished), let it blow air through the pipes for just a few minutes. Open every tap you have winterized and catch what comes out. It will be enough for the rest of the boat. Don't forget the transom shower.

- Close the glycol valve.

- Remove the strainer, clean, and put a little glycol in it. Yeah, I could just leave it off, but I know I'll forget in the spring and get a slight flood.

After reading Mike's link, I figured I should add these. I've also posted winterizing stuff here.

Shower Drain

I guess I might as well mention this, while on the topic. Pour about a quart in the drain and pump.

Sinks

They're all hose and drain anyway. Skip it.

Engines

They drain if raised.

_______________

The previous owner blew out lines and disconnected lines. I spent a season chasing leaks in connections that had been opened too many times and replacing cracked fittings on the water heater that didn't quite drain. This is MUCH better. The only thing lazier would be wintering in Grenada....

Tuesday, October 16, 2012

Hanging in there

George on m/v Grace (across the dock from us here on Eolian) has solved the problem of what to do with your kayak when at the dock. His solution keeps the barnacles off the bottom and yet makes the kayak easily accessible for quick use.

George built a kayak sling - using two wood slats and a sheet of some kind of plastic. The kayak hangs suspended out of the water, yet securely cradled.

George built a kayak sling - using two wood slats and a sheet of some kind of plastic. The kayak hangs suspended out of the water, yet securely cradled.

Here's a detail of the attachment of the plastic sheet to the wood slats. You can see that George cut a saw kerf in the slat and slipped the end of the sheet into it. What you can't see in this picture is that there are a series of screws driven crosswise thru the slat and the sheet, pinching the sides of the slat on the sheet.

Its a simple solution that does the job well.

George built a kayak sling - using two wood slats and a sheet of some kind of plastic. The kayak hangs suspended out of the water, yet securely cradled.

George built a kayak sling - using two wood slats and a sheet of some kind of plastic. The kayak hangs suspended out of the water, yet securely cradled.Here's a detail of the attachment of the plastic sheet to the wood slats. You can see that George cut a saw kerf in the slat and slipped the end of the sheet into it. What you can't see in this picture is that there are a series of screws driven crosswise thru the slat and the sheet, pinching the sides of the slat on the sheet.

Its a simple solution that does the job well.

Thursday, October 11, 2012

More solar power

A popular mounting location for solar panels is on top of davits. Here, Brian over at Dock Six makes some very minor modifications to the davits (which he also made!) to mount a new solar panel:

After several seasons of stalwart service, all-weather exposure, and an occasional dunking, Whiskeyjack's little 15 watt solar panel had finally tapped out. We had been planning to install a second 15 watt panel and a charge controller this winter, but the demise of panel #1 altered our energy management plan, our timetable and our budget.

It's time to explore the options.

Fellow blogger Dan Kim has written an excellent overview of solar options here:

Sailing Dog's Solar School

So, since he has done all of the heavy lifting, research-wise, I don't have to. Cool.

After weighing all of the options, including power output, weight, dimensions, delivery time and budget, we purchased a 40 watt amorphous panel/charge controller kit from our local Canadian Tire Store . It was on sale for $149.99 (50% of the regular $299 price tag), putting it over the "Low-Buck" threshold, but still inside our solar power budget.

Opening the box, I unpack sufficient cabling, an aluminum-framed panel approximately 3' x 2', a sufficient assortment of connectors, and a rudimentary (but sufficient) charge controller, and sufficient installation instructions.

Nothing impressive, nothing that screams "secret awesome deal!" Sufficient value at a hundred- and- a- half bucks, but not worth twice that price.

Installing the wiring and the charge controller took about 20 minutes. Figuring out why the battery wasn't getting a charge took twice that time. Turns out one of the sufficient number of connectors was insufficiently soldered. With that problem solved, the panel took up temporary residence atop the bimini while a permanent location was pondered.

Last week, I finally had the necessary convergence of available time, available parts, flat water and an empty neighbouring slip to finish the job. Earlier than I am normally ambitious, I cast off lines and warped Whiskeyjack out, around and back. Below, you can see the panel lounging on the bimini, and also it's new home- atop the davits.

First, another tie bar had to be installed, but only after carefully scattering an assortment of tools on the Dock, largely out of the way of the work area....

A few minutes of cutting and caulking and drilling and screwing had the additional tie bar in place.

After some measuring and remeasuring and some more drilling, this time into the frame of the panel, u -bolts were installed and nuts snugged down and the panel was firmly attached to its new home. The panel can be removed along with the tie bars for winter storage by simply undoing four machine screws and disconnecting the cabling.

The wiring was routed and secured and a shakedown cruise was taken.

Nothing fell off. Mission accomplished!

So far I am satisfied by the result. I'll keep you updated on performance over the next few seasons.

Total cost, including tie bar materials: $194.37

Total time: 3.5 hours.

Total tools sacrificed to lake: 1 hex key.

Tuesday, October 9, 2012

Dual purpose tell tales

Jeff on s/v Ces't la Vie solves a common problem with roller furling headsails - it's a simple and ingenious answer...

Seeking a break from the work in the engine compartment, I looked to the sails for a diversion. We added a roller furling 130% genoa last fall and are very pleased with the increased performance and ease of use.

After using the sail for one winter, I realized two shortcomings. First the only tell tales on the sail were aligned vertically with along the luff. Unless the sail was fully extended no tell tales were visible. When sailing to windward I rely heavily upon the forward sails tell tales to trim. Secondly, with our roller furling sail there was no way to quickly judge the percentage of sail aloft. "Did we unfurl a 80% jib or a %110 genny?"

With the sail off the foil for storm season the time is right to remedy the issues. By strategically adding tell tales I hope to kill two birds with one stone. C'est la Vie's "J" (the distance from her mast to forestay along the deck) is 184". Thus the foot of a 100 percent sail on C'est la Vie would measure 184". Each time we roll out or roll in 18.4" along the foot of our sail we are altering the sail area by 10%. Ok this is Jeff logic so someone out there is welcome to correct me if my logic is flawed.

To provide an indication of the amount of sail out I placed new tell tales at 37" increments (18.4" x 2 = 36.8" rounded up) back from the original tell tales along the luff of the sail. This will allow us to estimate sail area via the tell tales placed at 20 percent intervals.

Fully unfurled equals 130%. Roll in to the next tell tale equals 110%. Roll in halfway to the next tell tale and we have 100% aloft. Or perhaps more importantly if we roll out to the first tell tale we have a 70% head sail aloft. You get the idea? I placed three new tell tales along the lowest level and two at the second tier.

Thursday, October 4, 2012

Sealing Bomar hatch leaks

Eolian does not have this kind of hatch. But if your boat does, then Drew over at Sail Delmarva has these tips for you:

A wet bunk is just too much like camping out, so last weekend I fixed a few nagging leaks. Nothing, until a torrential down pour strikes, and then more than you want to deal with, several dripping at once. A few lessons learned:

About 20 minutes each. A little hard on the fingers, so do only a few each day. Not bad.

- Clean the sealing area. Particularly on the sloped hatches over the aft cabins, most leaks are actually caused by trash caught in the gasket area. Simple hose out and wipe with a cloth periodically. You may not need a new gasket.

- Replace the o-rings in the latches. Very easy and the cause of most minor leaks. Only a few minutes and no easy way to it screw up. If you decide to replace the gaskets, you need to remove the latches for working room anyway. Additionally, the increased pressure on the latches caused by new gaskets is know to cause leaks when old o-rings are recycled, so just replace them now.

- Defender sells the gasket material for the low-profile hatches used on the PDQs. You buy it by the foot and cut to fit, so there is less waste and it is cheaper than West Marine if you are doing several hatches.

- Standard "Goop" is a suitable adhesive for the Bomar gasket material (gluing the ends together--they are not glued in place). Trim with a razor and press the ends together. Close the hatch to dry (wax paper on the rim). The instructions said Super Glue, which is neater, but I was out. I have used both before (making o-rings at work) and they both work.

- Place the cut on the down-hill side. Obviously.

- If you ever replace the lenses, don't get sealant on the gasket. The sealant should only be between the lens and frame on the edge, and not much excess below the lens. Center the lens first, then inject the sealant, rather than placing the sealant and then dropping the lens in place.

- Try to place the gasket under slight compression; they shrink over time and will tend to pull away in the corners. No doubt you figured this out.

- Lube with water and a trace of dish washing soap to make it easier to slide in. A dull dinner knife tip can help shove the tab in the last bit.

Tuesday, October 2, 2012

What to do with a retired sail? Part II

Jeff on s/v C'est la Vie continues with Part II of his project based on an old sail (you may want to read Part I first):

After viewing a couple free how to videos on zippers from Sailrite, I installed a 60" zipper into the side panel of the future paddle board bag.Jeff refers to the videos available at Sailrite - I can't recommend them highly enough - they are excellent.

Next my attention turned to handles / lash points on the top and bottom of the bag. Concerned that the forces on the handles could cause the sailcloth to rip, I installed re-enforcement patches along the inside of the bag at the handle attachment points.

Using a zigzag stitch to avoid weakening the sailcloth, seven patches were sewn at 12" intervals along the mid-line of the bag.I then flipped the bag and utilizing the patches attached a continuous piece of one inch webbing to the outside of the bag.My next challenge is to create a slit in the bottom of the bag to allow the skeg to remain in place while the board is stowed in the bag.