The skunkworks deep beneath Stately Jones Manor could best be described as a low-tech production facility for thrifty wood-based solutions to nautical problems. However, occasionally there is a need to solve a problem with the solution.

Like how to make short wood longer.

(Get your minds out of the gutter, folks.)

Or how to drill a bunch of holes accurately and quickly.

Surprisingly, not every tool is available at Lee Valley Tools. Sometimes, you gotta build the solution to your problem. I had a couple of problems like that recently.

The Small Little Boat Company had a small real-money -paying refit job to accomplish over the winter- replacing the gunwales on a canoe. This project presented some unique challenges, starting with the empirical/geometric hurdle of working on a 16' long canoe in an embarrassingly cluttered 15' long workspace.

Once the logistics of the workspace were sorted, the scantlings of the job at hand moved to the top of the challenge list. The canoe required ash gunwales with an uncommon rabbet to conceal the top edge of the hull. Unless the customer wanted to pay biggish money for one piece full length un-rabbeted gunwales and truly rapacious shipping costs to transport the 16+ feet long wood sticks from the Big Smoke to Stately Jones Manor, I was gonna have to improvise.

So, improvise I did.

My local NOSLY (Neighbourhood Old School Lumber Yard, for those of you who don't remember acronyms used in past posts, or AUIPP) stocks local ash, a quickly disappearing stock thanks to the advance of the ash borer, in a variety of lengths... up to ten feet. Time to scarph.

Scarphing, or scarfing, (btw, note to readers: do NOT Google "scarfing" with your safe search off. Trust me) is a technique for connecting two too-short pieces of wood into one that is not, via a combination of mechanical and/or adhesive fastening and tapering the ends of the pieces to be joined, creating a seamless length, like so:

Courtesy of Wikipedia

Simple, right? It is.... except that the tapers have to be EXACTLY (or as close as possible) the same. If the angle or rise:run ratio varies, the piece will look like it has a waist or a belly and will not be straight. So, each end has to match. I have eight of them to cut. The chances of me getting even one correct taper working freehand is zero, so I needed a jig.

Right on time, Good Old Boat publishes an article on building a scarphing jig. Oddly for GOB, it was an article that was difficult to follow with few and poor photos. I thought I could improve on the design, so I set out to build my version.

As is often the case in all things nautical, there is no hard and fast rule to the angle ratio of a plain scarph joint. 8:1, 10:1, 12:1, 15:1 have all been used by somebody somewhere and often the thickness and species of material in question plays a part.. The most common scarphing ratios, however are 8:1 and 12:1, so I decided to build a jig allowing me to make the cuts with my radial arm saw quickly and easily in both ratios.

What does this 12:1 or 8:1 stuff mean?

Glad you asked.

A ratio of 12:1 means that over 12" of length, there will be a rise of 1". A one foot long ramp, would be only 1" high at the end if the ratio is 12:1, for example.

So, to build my jig I grabbed some of my seemingly inexhaustible supply of scrap furniture-based particle board, and cut off a piece a little more than a foot wide, making the 12:1 layout easy.

On one end I laid out a 12: 1 scarph, on the other end 8:1, and carefully marked them so I would remember which is which in the future...

Setting the scarph ratios is simple math. For 8:1, measure 8" along the edge and mark. At the mark measure 1" in, then mark. Use a straight edge to draw your cut line, from the corner extending past your "1" mark. Repeat the process for the 12:1 edge.

Then I cut a couple of pieces of scrap to act as fences along the scarphing edges...

Cut your scarphs and screw and glue your fences in place...

Screw and glue fences on each end to allow clamping to the saw table fence.

Now it is a simple task to quickly cut scarphs every time. Lay the wood against the fence, clamp to the table or the jig fence, slooowwwwllllyyy draw the saw through the wood. Done.

Once the scarphs were cut, the lengths were rabbetted and routed and finally epoxied together into full 17' lengths.

Then they were sanded, oiled, oiled again, sanded, oiled yet again, and finally installed on the hull:

The screws were bunged, the bungs were trimmed,

The whole works was sanded and oiled again, and out the door she went:

Although this jig was designed with a radial arm saw in mind, it could also be used on a table saw, with the addition of t-track to the bottom of the jig, allowing it to slide along the table.

Total time to build the scarphing jig: 40 minutes.

Total cost: $0. If you don't have any discarded cheap furniture laying around and have to buy NEW cheap plywood or particle board, total cost will be under $20.

I'm building a shelf for the hanging locker and I need some pin rail. This is one of the few times in the maritime glossary that the same term has two different meanings, so a little clarification is in order here.

On traditional sailing ships this is a pin rail:

Literally, the rail which houses the belaying pins.

In my case, however, pin rail is a decorative and functional rail installed to boat shelves to prevent the objects stored on those shelves from becoming unstored when the boat moves.

image courtesy of ThaiTeak Marine

Teak pinrail runs about $8-10 per foot.

I don't need teak.

I do need pinrail.

(Not to go off on a tangerine here, but those of you who have been following our seemingly endlessmeddlingimprovements to Whiskeyjack may have noticed the variety of woods used, with nary a mention of that stalwart maritime favourite, teak. Lots of mahogany, some cedar, even some pine, some oak, some ash, but no teak. My personal opinion is that teak below decks is often an unnecessary affectation. The big upsides to teak are it's weatherability and wet traction, neither of which is a big concern above the sole below decks. Note the use of the phrase "above the sole"- teak flooring is an exception, but it's necessity in this application is debatable, in my opinion. There are lots of other choices that will work just as well if not better than teak at a fraction of the cost. And the variety of woods adds a little character. As George Buehler says in Buehler's Backyard Boatbuilding, "I like looking at various wood grains and stuff.." Now, I have managed to scavenge an assortment of teak odds and ends from DonorBoat which may make an appearance in upcoming projects. Hey, I've got it, might as well use it. But I wouldn't buy it.)

Right, so back to pinrail. If I don't want to buy it, I gotta make it. Really, it's pretty simple stuff- some spindles, a top rail and a bottom rail, and a bunch of holes... that all have to be exactly the same spacing on both top and bottom rails.

Okeydoke, time to build a jig.

I measure up my drill press table...

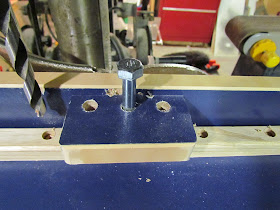

Then I scavenge some more of that old cast-off IKEA dresser that became a mitre saw extension , and I put together a drill press table, about 36" wide and about 8" deep.

I installed a couple of 1x1" x 6" offcuts to the underside of the table as cleats which straddle the drill press table. A couple of small clamps underneath hold the pinrail jig table securely to the table.

Now comes the finicky part.

After measuring the pin rail already affixed to Whiskeyjack, I discovered that the height was a constant 3", the width was a constant 7/8", the top rail was 5/8" thick, the bottom rail was 3/4" thick... and some rail had the spindles on 4.5" centers, others on 3.5" centers. Okay, so if I'm gonna build a jig might as well make a jig capable of building 3.5" center pin rail and 4.5" center pin rail, AND might as well toss in 2.5" center capability too, just for giggles.

So i needed to make an index block. Determine where the holes should be, find the center of the rails, determine the diameter of the spindles to determine drill bit size, etc.

With my index block set, it is a simple matter to drill three holes 1" apart on another offcut piece of IKEA dresser, and screw it to the jig's fence in the proper position as a center-setting block, as determined by the index block.

Drop an appropriate size bolt into the appropriate hole for the center desired to act as a stop.

Making pin rail is easy.

Rip two lengths of wood to the appropriate dimensions, then round the edges with a router or sander.

Lay the bottom rail on the jig table. Butt up the end of the rail with the bolt, lift the bolt and tuck the rail 1/2 way under the bolt. This sets up the first hole exactly on the desired center. If the rail was just butted up against the bolt, that first hole would be off by half the width of the bolt. Not a big deal, but it does waste a little material. Drill the hole, lift the bolt, slide the rail down until the bolt drops in the previously drilled hole.

Keep going until you run out of rail. Repeat the process with the top rail

Sand and install your spindles. Hardwood spindles can be bought in bulk for as little $.20 each, or if you want simpler looking spindles, cut your own out of dowel. I bought the ones pictured below. I couldn't MAKE them for what they cost- twenty two cents a piece.

Total time to build the jig and make the rail shown above: 3 hours.

Total cost: $0 for the jig, $3 for the spindles. If i had to buy the wood and the bolt to build the jig, material cost would be under $20.

...Unless you use teak.

This jig could also work with a hand drill, with one important modification- enlarge the center -setting block to incorporate a drill guide. In other words, build a block with one hole for the drill bit, and three more holes 2.5", 3.5" and 4.5" to the right for the stop bolt.

Life aboard is living large, in a small space. Every boat owner has found ways to make life in that small space easier, more comfortable, more convenient. The idea behind this site is to provide a place where these ideas can be shared amongst the boating community. To participate, send your contribution to SmallBoatProjects at gmail dot com.

Pages

▼

Thursday, April 26, 2012

Jigs

I have said it before: The really good wood workers don't just make things, they make tools - a high profession indeed, and one we should all learn from. Over at Dock Six, Brian has been at work and gives us two excellent examples:

Thursday, April 19, 2012

Tall Step Disease

Drew, over at Sail Delmarva, continues with this Spring's burst of projects. Today, he is dealing with the problem of out-of-proportion steps on boats:

As the knees get older, steps get higher. Last year, at the Annapolis Boat Show I was sitting on a 45-foot VERY expensive catamaran, along with a group of mature sailors who had the rocks to buy said boat. It was VIP and Press Pass Day and there were a lot of well healed folks about. Across the dock was an even more expensive Gunboat 50. Very pretty.

I pointed out that these boats all had tall step disease. A standard step is 7 1/2" x 10", yet even on the largest cats where space was no real concern, the step pitch measured 11" x 5", I suppose because it looked better. In conversation we also learned that fully 71% of our group had either personally or had a spouse go through knee surgery. Two artificial knees were displayed. My wife has an artificial knee, though she was resting it elsewhere, and I have had serious knee surgery. Are the boat builders so stupid--no, I don't think that is too strong a word--that they don't realize the buyers of these boats are either older or will soon become so?

Until now we have used the "runt box" you see under the helm seat. Honestly, only a 6'6" sailor can reach the floor while seated. We would move this box below the step, where it worked well. But while sailing it wasn't really available and own we didn't bother to move it.

Even younger sailor get worn down by big steps over the course of a long day--I can ride a bike 100 miles in 5 hours yet the steps get to me some days--and so I've been fighting my own battle, on a limited scale. The steps leading up from the cockpit are 14 inches and the steps down below are 11 inches.

I built these low stools (the cabin steps must fit under the swing of the bedroom doors) from scraps and a few squares left over from the cockpit floor project. Thus, they cost only a few hours left over materials. I don't think any real explanation is required for a carpenter to reproduce them. For the boat owner and tinkerer, hours spent making sawdust on small projects are not subtracted from out lifespan (yup, I bastardized that a bit).

Wednesday, April 18, 2012

Musings on the non-linear progression of projects

While refurbishing a dinghy, Jeff on s/v C'est la Vie waxes philosophical about the effects of our own aging on our projects...

The past few days have consisted of painting concoctions onto the dinghy only to then sand them back off. My progress measured by the increasing grit of the paper 80 grit, 120 grit, 220 grit. Today the dinghy restoration took a leap forward - Wahoo!

I completed the interior painting and installed the seat (pictured above.) Anne and I also applied the second coat of primer to the hull (pictured below).

If weather and schedule co-operate we will roll and tip the two top coats on Wednesday and Thursday.

My projects increase in complexity as my patience grows with maturity. Thus far in my life the complexity to patience ratio appears to be a linear progression. I wonder if the day will ever arrive that I am accurately able to estimate the the time such projects will consume. My current system is to double the time I initially estimate, but this equation is consistently turning up short on time. As I age and my projects grow in complexity should I continue to increase the multiplier for time allotted? Hmm, If this is true I better go ahead and get the big projects done before I pass a half century.

What of the non linear progression of projects? One day is devoted to 10 hours of sanding where progress in measured in grit. The next day progress is a apparent as a face lift on Yoda. Guess it's best to just accept the way of things and celebrate the days where progress is measured in fair hulls and dinghy seats.

Tuesday, April 10, 2012

Carburetor Bowl Vent Canister

Over at Sail Delmarva, Drew continues to be busy exploring opportunities. What kind of opportunities? Well, the kind that help protect the environment and make your engine(s) run better in the bargain. And he is a dedicated experimentalist...

Surely it appears I'm going overboard on this topic, but I love experiments.

If a carbon canister can reduce fuel loss and water gain in a tank, why not address the carburetor? Wouldn't this reduce gum formation and ease starting? And since it won't cost me anything but time in the shop, isn't it worth a go? Tiny carbon canisters have been fitted to California lawn tractors for some time, to meet stringent air regulations.

In automobiles evaporation emission systems tied the carburetor vent--back when we had carburetors on cars--to the main canister and flushed the system with intake air during operation. More efficient in terms of hydrocarbon destruction, but more complex and only effective if the car ran nearly every day. In fact, those systems did not reduce carburetor bowl evaporation, since they would never reach equilibrium. They actually drew gasoline from the bowl, much as calcium chloride draws water from the air. I've taken a different approach, since evaporation reduction is a primary goal, and that requires that the carbon reach equilibrium with the carburetor bowl while the engine is running, exactly the opposite sequence from what automobiles systems achieve. Since the carbon is saturated during operation--a warm engine encourages plenty of evaporation--when fresh air tries to enter the carburetor when it cools and at night, that fresh air will become saturated with gasoline vapors and will not contribute to further evaporation in the morning. This process of self-regeneration is about 65% efficient in reducing emissions for long time periods, according to EPA testing (page 5-120).

The carbon canister is above the in-line fuel

filter and is connected to the carburetor vent hose.Click to enlarge.

The canisters I installed are retrofitted from small in-line gas filters from the might-need box. Originally, they contained fritted bronze elements, which I had discarded (these were replaced by Raycor filters). I fitted each end with a carbon support screen cut from beach cat trampoline fabric. They hold 6 ml of granular carbon of a type optimized for low-flow gas phase hydrocarbon absorption. Though small, the carbon:gasoline volume ratio is much greater than used on tank vent filters, this is intentionally so; these will see much greater temperature operating temperature range because they are mounted beside the engine. Even the diurnal cycle will be greater, since the carburetor lacks the thermal mass of a fuel tank. They are NOT secured directly to the engine, as the high-frequency vibration is not good for the carbon. It is extended away from the carburetor, horizontally and slightly down hill, with 6 inches of hose to prevent fines from migrating back into the bowl. This is the existing hose, previously open ended and routed downwards between the carb and engine block.

What do I expect? Easier starting. Less idle jet gum formation and fewer stuck floats. I'll let you know.

___________________

Follow-up reports:

- Baseline, March 18. Both engines require primer to be pumped up if the boat has been help for a few days. Port requires 1-2 pumps of the throttle (Yamaha 9.9s have an accelerator pump). Starboard requires several pumps and several efforts, followed by an advanced throttle for a few minutes. Engines re-start within 18 hours, even if cold, with a single crank and idle well. Both engines are identical, purchased at the same time except for the carburetor; the starboard is a fixed idle jet US carb, and the port is Canadian with an adjustable idle screw.

- March 25. Easier starting after a week away seems to be confirmed. Both engines start on the first crank, without pumping up the primer or pumping the throttle. The starboard engine did not require the throttle to be advanced during warm-up and did not stall.

Thursday, April 5, 2012

Low buck dinghy - part finis

Over at Dock 6, Brian set out to design and build himself a beautiful stitch 'n glue dinghy, with design targets of:

Did he make those targets? This is the final part, following the previously published part I and part II:

- under 25 hours total working time

- a $250 budget

Did he make those targets? This is the final part, following the previously published part I and part II:

Uh-oh.

Trouble in low-buck city.

Epoxy is gonna be the budget-slayer. I can buy a WEST kit (32 oz.) for as little as $67, but I need more than one quart. In fact, I figure I will need roughly THREE quarts of epoxy. So, I can spend 3 x $67, which will blow the budget. Or, I can step up to the gallon size epoxy, which will run me about $120. Ounce for ounce, it is cheaper, but when i include the cost of fiberglass tape and cloth, i am going to be waaaaaaayyyyy beyond budget. I am going to go to Aircraft Spruce tomorrow and see if I can scramble a deal; they are a great source for composite supplies, even if what you are building will never intentionally take to the air. I gotta be able to pull the rest of it together for $148.00

Down to the final little jobs to make the boat at least rowable. I decided to fancy up the relatively naked transom with some trim that ties into the gunwales. It gives the boat a little character and also stiffens up the top of the transom. I grabbed a couple of conveniently sized 1x4 offcuts, and traced the cutlines:

Cut, sand, clamp, glue, screw, tah-dah!

And used some more 1x4 scraps to gin up some oarlock cleats:

Next up, cut and fit the foredecking, and finally resolve the centerboard/leeboard decision.

Oh, and I think I have come to a resolution regarding the budget issue. Those of you who have followed this soap opera will remember an earlier episode, where I bemoaned the fact that I may go over budget. This was an issue of honour for me. I threw down the gauntlet to myself, and I'll be damned if I'll come up short. But, I didn't want to sacrifice quality (?!), durability or safety to come in under my admittedly arbitrary fiscal limit. So, as I sit and ponder my dilemma, I re-read the crucial sentence from my first post on this project:< "The plan is to be able to get this bad boy built in under 25 hours total working time, on a $250 budget." AHA! I found a loophole! I never specified which currency! I did NOT specify American dollars, Australian dollars, Canadian dollars, Bajan dollars... If I figure my budget is $250 US dollars, and i have so far spent only $104.81 CANADIAN, then that means... (Carry the one, multiply by pi, divide by ... screw it. Google.) I have only spent $86 bucks US. I still have $164 left! that is $199 canuck bucks! More than enough to take care of the last of the materials! * **

* If i had taken advantage of the economies of scale,and built two or more dinghies, and taken a little more time nesting the parts on the plywood I could definitely have brought the individual material cost of each dinghy under $250 cdn. So, I have rationalized my rationalization.

** Remember, this was written early in 2009- our dollar was not the world-beating monolith it is today, in March 2011.

Right, back to it:

The following takes place between hours 19-21:

Pulled the trigger on the epoxy and glass supplies. I dropped a little more than 120 clams on FG cloth, FG tape, epoxy, fillers, spreaders pumps and chip brushes. Dropped another $6 at the dollar store on plastic pans and spatulas. Then, I set up a work space:

I spent more time than this project warranted on epoxy research, and in the end, chose West System. Why? It isn't the cheapest, (although on a project this size the difference between cheapest and most expensive was less than $50 ). It is not the most expensive. It IS, however, the best system, in my opinion. The pump system makes mixing resin and hardener damn near idiot-proof, the "by the numbers" resin/hardener/filler compatibility and selection really simplifies the process for both novices and pros, and their website has provided me with more information than every other epoxy manufacturers' websites combined. No exaggeration- spend a few minutes on the WEST system site, and you will begin to believe that epoxy can do damn near anything. In fact, I believe that WEST system epoxy may have killed Jimmy Hoffa.

Anyway...

So, now that I have a workspace kinda sorta almost organized, I start filleting. You may have noticed in an earlier installment of this series that the bottom of the hull was joined to the chines by zip ties - all of the zip-tied and screwed seams need to be fiberglassed to provide strength and watertightness. The only problem is that fiberglass doesn't like to be folded into sharp corners and angles. So, each seam has to be filleted- a mixture of epoxy and filler is slathered into each seam, and then tooled with to give a gentle radiused curve to each seam. I used high -tech tools to make nice neat fillets- a plastic spatula, a plastic spoon, a tongue depressor, and my finger. It's messy, and took me some time to start to get results that didn't look like it was squeezed out of an ex-lax addicted seagull. This is the end result:

While I wait for the fillets to set up, I install the inwales. The inwales compliment the gunwales, and add a little more rigidity to the sheerline:

And they look purty:

I had originally planned to work methodically- fillet the inner hull, tape the inner hull, epoxy the inner hull, then do the outer hull, but I discovered that a big roll of fiberglass cloth really complicates a small workspace. Sooner or later, either that roll of cloth was gonna get damaged, or I was gonna get damaged tripping over that roll of cloth, or both. So, I decided to work outside in, instead of inside out.< I flipped the hull...

removed the screws, filled the holes and any voids in the hull with thickened epoxy, then rolled out my cloth:

I cut off the excess, and mixed up some epoxy, and poured it on...

...and then worked like a tweaker with a free box of twinkies. I had a chip brush in one hand, a squeegee in the other, working the epoxy into the glass before it kicks. I'll need to throw on another couple of coats to completely fill the weave and level out the cloth before I paint.

Hours 22-24.... May 20/09- June 28/09

In addition to building dinghies, I actually have a real job that has had me working like crazy, and the pace shows no sign of letting up. The good news is that the money is stupid, but the bad news is that I have been, and will be, earning every penny - long hours and big headaches. Therefore, I have to work like an epileptic over-caffeinated orangutan on crack to get this dinghy in the water soon. So, here we go:

After another coat of epoxy to level out the hull, I flip the boat over. I have been retaining packing styrofoam from all of the consumer goods my household has purchased since I began this project, and proceed to cut and fit the various bits of foam to fit under the transom seat, then epoxy the seat into place, forming a (hopefully) watertight flotation compartment aft. I do the same thing ahead of the forward frame and now both ends are closed in. I tape and glass the seat slats for rigidity...

and then scratch my head to come up with a way of retaining them in the boat that will allow them to be easily repositioned. I settle on a system of small bungie cords attached to both ends of each slat, which loop over wooden IKEA knobs repurposed as cleats.

Tack another $10 onto the material bill for a jar of small cheap bungie cords. The budget is getting TIGHT... and so is the timeframe.

So, let's get to gettin'. I measure and precut all of the fiberglass tape for the seams, number them for clarity of assembly, pump some epoxy and start glassing the seams- thanks to precutting and numbering, I am able to get everything wetted and glassed in less than 30 minutes. The leftover epoxy gets slathered on the hull rather than wasted.

Once everything cures, I can sand, fair, and paint.... and this is where having the right tools comes in handy.

Then, i flip the hull...again.

I cut an offcut of luan to the height of the hull, and trowel on fairing epoxy then, using my new custom paddle that I bought at Aircraft Spruce, proceed to wipe most of it off the hull. the less there is on the hull the less i have to sand off. I quickly sand the hull down to something resembling smoothness ( providing the viewer is at least 20 feet away and is legally blind) and get ready for paint, and... crap! forgot to build a skeg!

Quickly rummage through the offcuts, find a likely candidate, cut, shape, screw, glass, fair...

...okay, NOW I can paint. add another $9 to the build tab for a quart of paint and....

Tah-dah!!!!!!!!

It even manages to escape from the basement without any home renovation required.

I bought the little 3.5 hp outboard for less than $120, and it seems like it will do an adequate job... I hope.

Now for the final tests- 1) can i get it to the marina in one piece, and 2) will it float?

Okay, first hurdle- getting it to the lake. I'd like to be able to take credit for the next miracle, alas i cannot, it was simply the serendipitous convergence of coincedence and blind luck, but, ....

"Chirp" fit in the back of my VW van like a hand in a glove.

And, she floats like a dream, and tracks true on her painter, and looks right at home on the dock...

and SWMBO thinks she rows great!

After making a couple of runs with the outboard attached, we decided to ditch the motor for two reasons- One, it was a recalcitrant two stroke that required an exceedingly long pull to start, and short boat + long pull = capsize. Two, it had no neutral, so once it DID start, you had better make damn sure you were pointing in the direction you wished to go. The plan for next season is to employ a trolling motor, with the battery stowed ahead of the thwart, which will also give Chirp some needed ballast. The upside is that she is light, making her easy to handle, and not much of a drag on speed when towed, and easy to row. the downside is she is light, making her a little tippy and subject to weight transfer.

Would I do it again? Yes. It was a fun build, I am pleased with the results, everyone who has seen her has complimented her, and now that I have the design and the bugs ironed out, I can get shave build time on the next one by about 20%...and if I build two or three at a time, the aggregate build time drops dramatically. Next project, though, is to build some davits for Whiskeyjack.