Life aboard is living large, in a small space. Every boat owner has found ways to make life in that small space easier, more comfortable, more convenient. The idea behind this site is to provide a place where these ideas can be shared amongst the boating community. To participate, send your contribution to SmallBoatProjects at gmail dot com.

Pages

▼

Thursday, December 25, 2014

Tuesday, December 23, 2014

Liebster!

Bloggers do it for nothing.

Well, almost all of us do it for nothing. I certainly do it for nothing anyway.

Well that's not exactly true. I blog because I get enjoyment from telling stories and from helping others solve problems.

But every so often, something great just falls out of the sky... in the blogosphere, there is a way that bloggers recognize other bloggers: the Liebster Award. Like those coupons in the newspaper, it has no cash value (rats!). But it is a huge honor to receive, because it is bestowed by those who know the business best: your fellow bloggers.

Aside from the awarding of honor to a fellow blogger, one of the purposes of the Liebster Award is to bring recognition to bloggers with small followings - bloggers who have a following less than that which they might deserve. We certainly fit into that category here. Well, the "small following" part anyway.

Like most things on the InterTubes, the meme of the Liebster Award has morphed as it was passed from blogger to blogger, thus there are any number of rules associated with it. This is the set I like and choose to follow. Except for that nagging and presumably arbitrary "11" part.

Thank you Brian, of Dock Six Chronicles for nominating Small Boat Projects for the Liebster! But I cannot in good conscience take credit for the award. This is a community blog - it exists only because of its contributors (over there on the right). The Liebster belongs to them, not to me. Because of that, my response is going to be a little unconventional - it will come in two parts. First, I will answer the questions posed by Brian myself, because I cannot imagine any way to get 35 (if I counted right) folks to agree on answers:

OK all you contributors, here is your challenge. Please supply at least one nominee, and at least one question that that nominee will have to answer. You can do this in a comment, or via email (to smallboatprojects at gmail dot com) if you do not want your response to be made public. I will compile the nominees and pick the top 3-5 (11?) of them, and I will compile the question list from those you supply. Then I will make a second post with the Liebster response.

OK - it's your turn... you're up.

Well, almost all of us do it for nothing. I certainly do it for nothing anyway.

Well that's not exactly true. I blog because I get enjoyment from telling stories and from helping others solve problems.

But every so often, something great just falls out of the sky... in the blogosphere, there is a way that bloggers recognize other bloggers: the Liebster Award. Like those coupons in the newspaper, it has no cash value (rats!). But it is a huge honor to receive, because it is bestowed by those who know the business best: your fellow bloggers.

Aside from the awarding of honor to a fellow blogger, one of the purposes of the Liebster Award is to bring recognition to bloggers with small followings - bloggers who have a following less than that which they might deserve. We certainly fit into that category here. Well, the "small following" part anyway.

Like most things on the InterTubes, the meme of the Liebster Award has morphed as it was passed from blogger to blogger, thus there are any number of rules associated with it. This is the set I like and choose to follow. Except for that nagging and presumably arbitrary "11" part.

Thank you Brian, of Dock Six Chronicles for nominating Small Boat Projects for the Liebster! But I cannot in good conscience take credit for the award. This is a community blog - it exists only because of its contributors (over there on the right). The Liebster belongs to them, not to me. Because of that, my response is going to be a little unconventional - it will come in two parts. First, I will answer the questions posed by Brian myself, because I cannot imagine any way to get 35 (if I counted right) folks to agree on answers:

Now for the second part...

What cruising destinations are on your sailing bucket list?

- BVIs

- Bahamas

- Barkley Sound

- Obviously (or perhaps not...) the first two would involve bareboat charters.

What piece of gear onboard did you purchase in the belief it would be essential, yet has hardly been used?

What was your longest passage?

- A Happy Hooker. Eolian's bow is a long way above the water. Hooking the ring on a mooring buoy and then lifting that really heavy chain up high enough to thread a line thru is a task that takes both of us. After pulling the bronze end off of our boat hook at Fort Flagler State Park, we bought a Happy Hooker thinking that would make it much easier. But we have not taken a buoy since that event. Frankly, anchoring is just easier.

What has been your scariest, "I'm gonna die!" moment?

- Define "passage". If you mean the longest distance over which the boat was in continuous motion,

What tools do you keep aboard?

- We were at the south end of the Strait of Georgia, coming up on a lee shore at Silva Bay in a howling downwind gale. Jane went forward to douse the sails, but just as she got to the mast, the staysail jibed and its boom knocked her over. From where I was at the helm, I couldn't see her - my heart was in my mouth because I feared she had been knocked overboard. Then she stood up, holding her head.

Things like this don't happen on a calm sunny day - they almost always happen at the worst possible moment. If she had gone overboard, even on her tether, I would have been faced with a man overboard incident while roaring down on a lee shore with the sails still up, singlehanded. Oh yeah, and the water was lethally cold.

Yeah, it scared the daylights out of me.

What has been your most satisfying sailing accomplishment?

- All of 'em. No, really. It's a fetish that Jane has to live with, but we have enough tools aboard Eolian to handle just about any eventuality, short of a complete engine rebuild, maybe. He who dies with the most tools, wins, right? And besides it is a two-way street: I have to live with Jane's shoes.

How has your sailing life changed you?

- I think I would award this to out trip to Desolation Sound. We were off the dock (off any dock) for more than 30 days, a simulated trip to the Marquesas, but without the warm water. The only thing we ran out of was stowage for garbage.

Are you sailing your perfect boat? if not, what would you change?

- We have been sailing since 1972... it is difficult to remember a time before sail. Surely there were changes as a result - was there a time when we did not worry when the winds went above 25 kt? Certainly there must have been.

Link your most popular blog post.

- For us, Eolian is the perfect boat. She is the fourth boat we have owned, each successively longer (of course), and the ballast in each outweighing the entire previous boat. For the kind of cruising we do, I cannot imagine a boat better suited to us.

Link your personal favourite blog post.

- As you might expect, this changes over time; the current favorite is this one.

- To date, there have been 510 posts on this blog, nearly all of 'em by our contributors. No way am I going to show favortism by singling out one of our authors. But so that the question doesn't go unanswered, I'll link to one of my favorite posts on a blog that I do write: here.

OK all you contributors, here is your challenge. Please supply at least one nominee, and at least one question that that nominee will have to answer. You can do this in a comment, or via email (to smallboatprojects at gmail dot com) if you do not want your response to be made public. I will compile the nominees and pick the top 3-5 (11?) of them, and I will compile the question list from those you supply. Then I will make a second post with the Liebster response.

OK - it's your turn... you're up.

Tuesday, December 16, 2014

Chap Chap Dinghy Chap

Dinghies in the tropics are subjected to the full force of the sun's destructive UV in a way that those of us up north can barely comprehend. Even the most expensive Hypalon is corrupted by the sun. What to do?

Valerie & Laurent, aboard s/v Letitgo (currently enroute from Ecuador to the Marquesas), addressed the issue by making "chaps" of sunbrella that cover the dinghy's tubes... not an easy task, but well worthwhile!

Valerie & Laurent, aboard s/v Letitgo (currently enroute from Ecuador to the Marquesas), addressed the issue by making "chaps" of sunbrella that cover the dinghy's tubes... not an easy task, but well worthwhile!

The last four days have kept us pretty busy; a dinghy chap is not an easy sewing project and was on our list for a while. Indeed, the shape is complex with all the curves add to that the handles it definitely needs a minimum of precision to achieve something that looks half descent. The pattern had been done while we were in Panama, along with the purchase of the fabric, so we were ready. In the end, we are still talking to each other, I (Valerie) have gained even more confidence in my sewing machine and learnt a few tricks of the trade and that’s all thanks to Mum who gave me many memories to cherish and new knowledge. As for the guys they kept clear at all times from the working area and provided us with delicious and nutritious lunches every day! Thank you for that too.

We won’t be the ugliest dinghy on the dock or surfing the wave anymore!

Thursday, December 11, 2014

Tiller Conversion

Over on s/v Suppose, Walt & Kathy take an unusual step... And in the process demonstrate some nice prototyping skills:

Suppose, suppose... Suppose we had a tiller instead of a wheel in our boat. Wouldn't the cockpit be much more spacious, wouldn't the mechanical complexity be much less and the reliability much greater, wouldn't it be easier to feel the boat and balance the sails, and wouldn't a wind vane be much more effective. All good reasons but when we suggested the conversion to most of our sailing friends, they thought we were nuts.

pic 1

pic 2

pic 3

pic 4

pic 5

pic 6

pic 7

pic 8

pic 9

pic 10

pic 11

pic 12

pic 13

pic 14

Tuesday, December 9, 2014

A Platform To Stand On

Metal fabrication is not a frequent topic here because of the specialized skills and tools it requires. Nevertheless, good communication skills can substitute for those, as Ken of s/v Painkiller demonstrates:

Not too long ago on the Pearson 424 forum that I hang out, someone asked if there was any information or drawings, or possible "who" fabricated the anchor platform that was offered to Pearson owners when having a new boat built.

Nobody had any concrete answers, so I offered to the gentlemen inquiring that I would give him an accurate detailed drawing that he could have the exact piece reproduced from any competent fabricating shop.

All I had to do was go forward with measuring tape, paper and and pencil. I noted in my drawings (I shared with the forum) that I would add a third or fourth point to stiffen the platform as it seemed to me it having a weak spot with potential heavy loads from getting a stuck anchor off the bottom. Not to mention that mine was bent at least 5 degrees....I never noticed it till I starting measuring for the drawings.

I had some ideas and traded some unwanted stuff at Sailors Exchange in St Augustine, FL for some various bits and pieces of stainless steel hardware that I could fabricate into something to help beef up the platform. A 1/2" U-Bolt was my starting point. The actual finished bracing point saw a few different ways before I settled on a robust 3/8" plate that supports the brace for the anchor platform and offers me a point near the waterline to lead a snubber line for anchoring. After coming up with a definitive plan, I removed the platform and brought it to a local shop to have straightened and weld up my various pieces.

I backed it all up with 12" x 5" shaped block epoxied into the forward stem. Not sure if I would tow my boat at sea in an emergency from this point, but for sure at anchor it will be fine.

I'm thinking this will take a load off my concerns of have an oversize anchor bury itself a little deep and need some persuasion to pop it free.

Wednesday, December 3, 2014

Snag Reduction--Or Tacking Without Tears

Tacking a boat is a time when all kinds of mischief can occur. With all the sails and sheets loose and being blown/flogged around, it is amazing sometimes what Murphy can pull off. Over at Sail Delmarva, Drew implements one of his typically elegant solutions to keep him in check:

Snagging the lazy genoa sheet on the mast-mounted winches has been my curse since the first day. The clew is just above the winch, and when it slides across the mast during a tack it just loves to loop over the winch, necessitating a trip forward. If I'm lucky, the boat doesn't fall into irons.

I tried a few simple bungees and covers for the winches. No luck. I tried better technique; OK when the wind was light, but otherwise undependable. I tried a line from the spreaders forward to the tramp; too hard to get the tack around. Finally I spent some time looking at it and found a simple solution that works the charm.

The Deflector. I ran a 40' length of 1/4 spectra double braid that I had left over from the end of the self-tacker traveler, through the lazy jack pad eye at the spreaders, and down to the other end of the traveler. It is tensioned with a truckers hitch, but not too tight, as the forces could get out of control. This keeps the sheets away from the winches AND away from the salon hatches , allowing them to remain open even when tacking. I thought it might be in the way, but in fact it makes a nice hand hold in an otherwise precarious area.

The sheet is held far away from the mast and hatch.

However, there is a significant tendancy for the clew eye and soft shackles to jam against the new deflector stays. I tried a few things before coming to a simple and entirely satisfactory solution; the sheets are now attached to the tack via a trianagular sliding bridle.

The Bridle. an 18-inch spectra climbing sling did the trick. It is luggage tagged to the eye and then each sheet is attached with a separate soft shackle. If there is any tension at all on the lazy sheet, the sling opens up into a triangle and sail clew is NOT forcibly dragged across the stay, only the sling. The clew eye is always free to move forward, away from the stay. Additionally, the shackles do not pass all at once, but rather in succession, reducing the drag.

A bit tricky to see, but both sheets are attached NOT to the clew, but to the sling, along which they are free to slide when tacking. Both are attached with soft shackles; this is required because the windward sheets are inside the shroud and the reaching sheets are outside the shroud.

Not a single snag over many tacks in many wind conditions, from ghosting to 25 knots. Why does it take so long to learn simple things?

Thursday, November 27, 2014

Thanksgiving

In America the last Thursday in November is set aside for giving thanks for all that we have.

Those of us in the boating world have things to be thankful for that the average American can only vaguely understand...

Those of us in the boating world have things to be thankful for that the average American can only vaguely understand...

- The quite peace of an anchorage at dawn, coffee in the cockpit

- The look of filled sails against the sky

- The feel of a boat as it slices thru the waves, propelled only by the wind

- The stark beauty of a rocky islet topped with a cap of evergreens

- Gulls (no, really - they are the most accomplished and graceful fliers ever)

- A nite sky filled with an infinity of stars

- Sleeping to the sound of water gurgling against the hull

- And... sunsets

Tuesday, November 25, 2014

Preparations for Ascending the Mast

Climbing a mast is arguably the most dangerous thing you can do on a boat. Before you take on this task, you should go over the task(s) to be accomplished at altitude and make detailed preparations. Rick on s/v Cay of Sea shows us how:

I installed new deck hardware back in May of this year in preparation for a rigging project. The original idea was to ascend the rig, drop the headstay to the deck, build a new stay then climb the mast again and install it. But there were things to do before I would go up the mast, and one of them was replace the worn out deck hardware through which the line passes.

The second item in preparation was to replace the halyards. I researched the ageing characteristics of the StaSet X line that I use for halyards, and it was obvious that the line was plenty strong, even after 7 years’ service, to support my weight. But I wanted a comfort factor that the old line wasn’t going to provide. New line for halyards was called for. The final crippling of my standing rigging as a result of having the steel wire come out of the spreaders kicked me out of procrastination mode, and I ordered the line. About the same time, I noticed an area of chafe where the main halyard passes over the masthead sheave. So it was time to replace halyards, and now I have no guilt over being wimpy about going up the rig with new line.

300 feet of 5/16 Sta Set X.

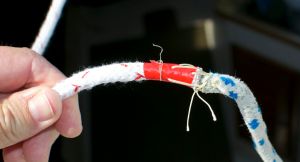

I ran the new line up the mast today. I sewed the new line and old line together at the ends, then covered the seam with duct tape, so it wouldn’t catch in the sheaves at the masthead. When connected and smooth, I simply pulled on the old line until I had new line in my hands.

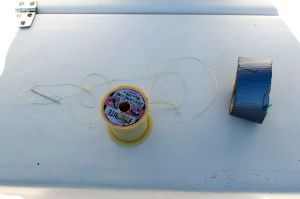

Tools for installing new halyards: sail repair needle, heavy nylon “squidding line,” and duct tape. A pocket knife is useful too.

Line ends sewn together. This makes a strong attachment that won’t let go. I wouldn’t trust tape alone.

Seam covered with duct tape.

Tomorrow is the day, at least for Part I. I spent an hour today figuring out exactly what I’m going to do up there, organizing supplies, tools, and procedures.

Supplies

Seizing wire, spreader boots, rigging tape, ring and split pins, deck and steaming bulb, 2 halyards, 2 new blocks.

New 70′ halyards. Had to measure 4 times before I started getting the same length of line consistently. Then cut entire length (140′) in half.

Tools

Essential tools. Piece of material under the pocket knife is emery cloth for polishing 12vdc light contacts.

Canvas buckets to the rescue: Tool bag on left, supplies on right.

Order of Work

2. At Steaming/Deck Light

- At spreaders:re-slot cap shrouds and wire/seize in place

- install spreader boots

3. At masthead

- Replace bulbs and test while aloft

4. Descend to spreaders and inspect all fittings.

- Attach new blocks, tape shackles/circular retaining pins

- Rove new line through blocks.

- Use one new line as temporary headstay

- Attach other new halyard to harness as safety line (another deck helper tends this line)

- un-attach old spin halyard

- un-attach furler/headstay and lower to deck

- Check fit of old (original) stay to hardware for match

- pin size conflict at stemhead leaves doubt that masthead hardware matches

- Visually inspect all fittings

Already done

Un-attached furler from stemhead, and secured to rail. Attached old spin halyard to bow pulpit for temporary headstay.

Old furler secured to pulput, removed from stem.

Final Photo – is this where we got the term “poop deck?” Birds have been doing me wrong!

Friday, November 21, 2014

Sail Struggles

Walt and Kathy of s/v Suppose put their Sailrite LSZ-1 to work making sail modifications. [Sailrite LSZ-1 - don't leave home without it! -Ed]

In January 2013, we made the decision to modify our sail plan and brought the main and genoa sails to Lubbock. We ripped and picked the seams that attached the sacrificial sunshade and the furling wire on the genoa. The main sail lost its battens.

In June, we purchased a new Sailrite LSZ-1 industrial sewing machine. This heavy-duty machine allows us to modify our sails, make protective covers and a large sun screen, and to reupholster seat cushions.

Because the genoa (140%) is our largest sail and had the most extensive modifications, we started with it. Oh, ambition! It has been a frustrating but satisfying exercise. Here are those modifications:

Triple stitch the broad seams. The broad seams are the ones that go across the body of the sail. Because the Sailrite does not do a true triple stitch (three small stitches to form each leg of the zigzag), we opted to reinforce the seams by adding another row of zigzag stitching. The greatest challenge of sewing on sails is the shear volume of cloth involved.

Replace furling tape with hanks. Many sailboats use furling systems to dowse their head sails. Our previous two boats had such systems, and we quickly became dissatisfied with them. On both boats, we had furler issues such as jamming that would be incredible issues at sea. For Suppose, we have opted to convert the genoa to an old school hank-on sail. To do this, we replaced the furling tape with a bolt rope on the leech edge of the sail. Then grommets were installed behind the bolt rope and the hanks were "seized" on the bolt rope.

This bolt rope bears all of the tension load when the sail is hoisted rather than the sailcloth. For this reason, Kathy created eyesplices around metal thimbles at both ends. The leather goes around the rope first to protect it from the chafing of the metal thimble. Then, the rope is spliced to hold the thimble in place.

Hand-sewn leathering prevents chafe while the webbing secures the thimbled eyesplice at head (top) of the genoa foresail. The contraption on my hand is a sailmaker's palm to prevent me from impaling my hand with the large needle needed to pierce the numerous layers.

One of three needles I broke or bent while hand sewing the leather chafe guards.

Wednesday, November 19, 2014

IKEA stuff for Boats?

To do any fun cooking aboard, you need to have at least a basic assortment of kitchen tools (See? This is a manly post - it's about tools!). And more to the point, you must find a way to store them. And there's the rub - there's never enough space for all your tools. Aboard s/v Dulcinea, John found a solution, at IKEA of all places:

Dollar conscious IKEA Bling!

I have always had this annoying problem in the Galley... I had spatulas, serving spoon, Pasta Rake and so on, but they were just too big to fit in the Drawer. So I stowed them under the stove, but that wasn't working out too well either. they were hard to get to under there, and they seemed to always slide out onto the sole (floor) on a good starboard heel. I was also bothered by all the wasted space behind the stove... at least 8 to 10 inches of usable space...

Enter IKEA. When he found out I had never been to this superstore before, My Brother in law took it upon himself to hijack me on the way back from Bellevue to take a look-see..... Wow, they had a LOT of cool stuff there. I saw a closet organizer I really wanted, but it was too big and too much ($1500) to consider purchasing that day... but they did have something for Dulcinea that might ease my Galley Woes....

OK... I know what you are thinking.... what the .....? a towel bar? well it is a bar, but it is for the Galley.... just the thing to organize my utensils that won't fit in the drawer.... watch closely!

Now this is a very simple install... 4 small screws hold the bar in place. But.... NOTHING is simple on a Boat... First, I had to remove the stove so I could install this baby. I didn't want to completely disconnect the gas line or power, so I sat it on the sole...

the small space the stove fits into... with the stove on the floor in front

Next I had to put myself in the "Backwards cramming into impossibly small space" Boat Yoga pose, to awkwardly drill into the counter, and then put screws in to anchor the bar in place

My torso crammed into the small space

The only place for my legs was on top of the stove and the Galley Counter...

Then, while in this really uncomfortable position, somehow measure, drill holes into but not through the counter, then screw in some small S/S Screws to hold the bar in place. I was originally going to mount this to the back (really the port side), but why drill any more holes into the sides of your boat than you have to?

Now it was time for the Test... I also bought S hooks with the bar, as well as a little cup that hangs on the bar. I put them on and hung some stuff... looks pretty good!

about an hour later, the bar is secured

The test hang....

Finally, I had to consider that this is a Sail Boat, that, when underway with the sails up, will not stay level. I didn't want all that stuff banging around back there, or falling off when in a steep heel, so I found a use for some really small Bungee cords I had laying around....

.... And a Bungee cord shall secure them....

Now, to put the stove back and see how it all fits...

all stored away... in some previously unused space!

My Initial impressions are that this will work well! I will let you know more after I try it out on some extended trips...OH! and the best part of this whole thing was the price! I got the Bar, the hooks and the hanging cup, all for about 5 bucks! with tax! And Dulcinea gets some IKEA bling!