The hatches on

s/v Painkiller needed attention. Ken tackles a complete rebuild head-on:

After seeing the replacement cost of these old style offshore hatches we actually went and bought three, one step down, Bomar replacements for just over a $1000. After getting the new ones back to the boat we took a closer look at them side by side with the old ones. Wow! We brought the new ones back for a full refund. Let's keep the old ones and rebuild!

Once started, the old lenses came right out. A couple of these were leaking and it seemed to me that the lens were at one time cut too big and not given enough room to expand and contract. Should be (I think) about an 1/8" per foot of lens, 2' hatch=1/4". Google it, find out for yourself.

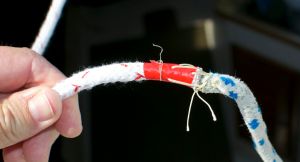

The dogs came out just as easy with an 1/8" punch and small hammer.

Very simple construction, a shaft, a dog, couple of pins and a tightening nut.

Old dry gasket material just as easily came right out.

Lots of wire scraper, wire brush and sandpaper cleaning of all surfaces inside and out, it's kinda therapeutic for me, I just love making things better!

Sorting through all the dog downs, deciding what is worth keeping and or repairing and how many "new" complete kits to buy.

I filed and tuned up most all the dogs, had to make a few new shafts with material I had at hand ...

... to give me one hatch with 4 new bronze and brass studs, one hatch with original aluminum studs that were in good condition and one hatch with all new kits at $35 a kit. That's the one in the galley, used the most.

Using an old lens re-cut for more clearance, with a router I traced the new stock for a proper fit.

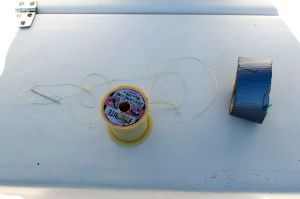

Zinc Chromate for the bare aluminum and a couple of coats of paint, let dry for a few days and...

... mask everything then...clean, clean and be careful of even your fingerprints as handling the new lens ...

... lay on the goop for a waterproof shiny new hatch.

I didn't get any pictures of laying in the new gasket. it went simple enough after a thorough cleaning and then clamping the hatches in place for a couple of days.

A total of about $100 per hatch, what's not to love about that?