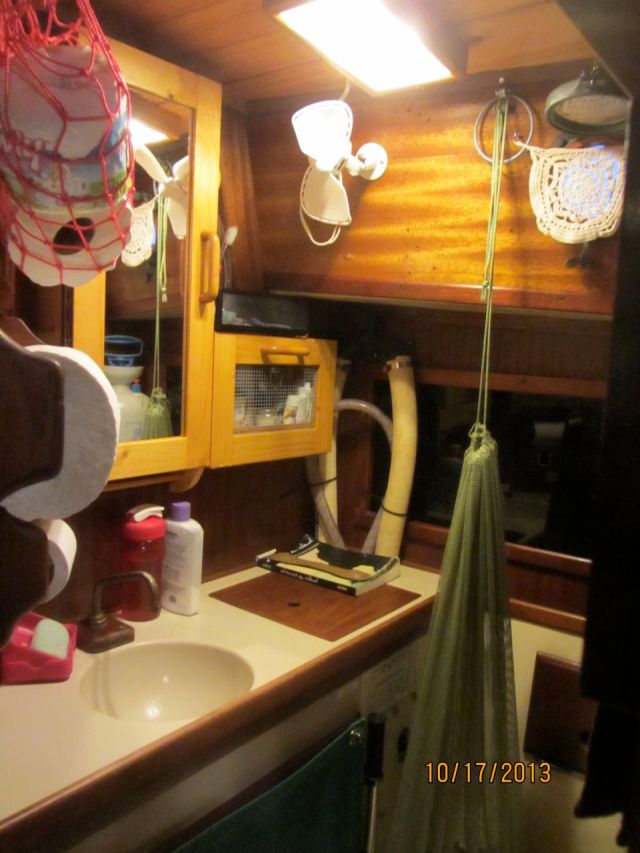

Chopsticks are Jane's go-to tools, whatever the problem. This frequently has me looking all over for them when I make a Thai curry for dinner.

One of the most frequent problems she solves with chopsticks is the escape of our wine glasses from the wine glass rack attached to the underside of the cabinet above the galley sinks. She jams a chopstick diagonally into each "track" to keep the glasses from jumping ship in a seaway.

In January of 2012,

I shamelessly asked you Small Boat Projects readers for ideas on how to remedy the escaping wine glass problem, sadly having drawn a blank myself (I am embarrassed to admit).

That was nearly two years ago. The

many 50 3 of you who read this blog probably thought that I had forgotten the whole thing. Not so.

A lot of great ideas came in - thank you for lending me your creativity! What I ended up with is a combination of a couple of the ideas you let me have...

First, I bought a package of small neodymium magnets; they are 1/4" in diameter and perhaps 1/16" thick. I got them at a local hardware store (

Hardwicks) that is still in the old mold - it is a jam-packed building with stuff stuck everywhere in every nook and cranny. All the regular things you'd expect to see in any hardware store, but also unusual stuff that somehow crept in and hid itself in odd places.

Next, I cut a teak strip sized to close off the exits of the wine glass tracks in the rack. It is the same thickness as the bottom strap of the rack so that it will lay flush with that bottom strip when it is in the open position, thus not providing an edge for a glass to catch on when it is being removed from the rack.

Then I used a 1/4" forstner bit to bore holes just deep enough to accommodate the magnets - two in the teak strip, and two at the matching points in the rack. I then epoxied the magnets into the holes.

Finally, I applied a pair of tiny hinges to the teak retainer strip, located in such a way that when the strip is folded up, it closes off the exit tracks and ends up flush with the edges of the track pieces.

And then, finally, a few coats of varnish and mounting.

|

| Retainer open |

|

| Retainer closed |

I had originally planned to let a couple of the magnets into the bottom of the cabinet to hold the retainer strip in the open position. At the moment, the hinges are stiff enough that this is not required (I probably got some varnish in there).

One thing that made the job a little tricky... the magnets are unmarked as to N or S poles. And they are tiny little things. With my big clumsy fingers it was all too easy to flip them over unintentionally, and more important, unknowingly. It would have been a disaster if I got one of them glued into position upside down... I tested (and retested...) with a spare magnet to make sure that I had the polarity correct.

Finally, a tip of the hat to you readers who contributed suggestions! Thanks - I couldn't have done this without you!

(And a rhetorical question: Why don't the manufacturers of the wine glass racks do this themselves?)